Hariom Pipe Industries Limited, an integrated manufacturer of premium steel pipes and tubes, is exploring new growth opportunities, enhancing its offerings, especially in the value-added product category, and investing in cutting-edge technologies to stay ahead of the curve. This was revealed by Mr. Roopesh Kumar Gupta, Managing Director, Hariom Pipe Industries Limited, during an exclusive interaction with Tube & Pipe India.

Tube & Pipe India: Kindly Walk us through the illustrious business journey of Hariom Pipes, highlighting major milestones and crucial achievements.

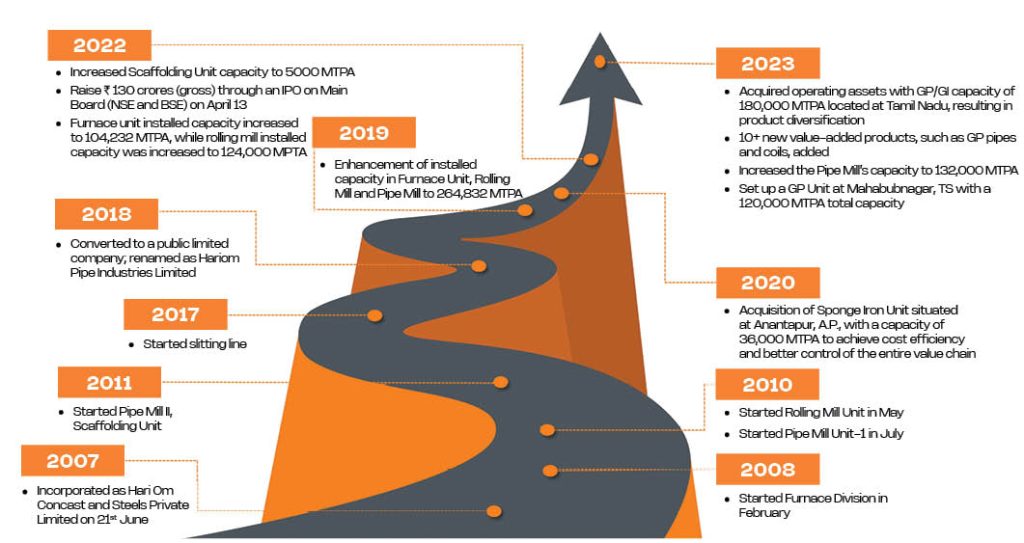

Roopesh Kumar Gupta: Hariom Pipe Industries Limited is a part of the prestigious Hariom Group, headquartered in Hyderabad, Telangana. The group was founded by industrialist late Shri Hariom Gupta in 1962. From its roots in trading steel pipes and tubes, we have gone from strength to strength, evolving into an integrated manufacturer of premium steel pipes and tubes. In 2007, the company was incorporated by the name of Hariom Pipe Industries Limited. Since then, we have been consistently adding to our rolling and pipe capacity. Under the leadership of Mr. Roopesh Kumar Gupta (Managing Director) and Mr. Shailesh Kumar Gupta (Whole-time Director), the company continues to thrive, supported by a dedicated and skilled team. Together, they drive innovation, uphold the highest industry standards, and ensure the production of premium steel pipes and tubes.

Today, we are proud to be a fully integrated manufacturer having a wide range of value-added products, a well-established dealer & whole-sellers network across the South Indian market, strong backward integration capabilities, a 840 plus member team, rich industry experience of more than 50 years and above all, a strong brand presence with top of the mind recall. A large percentage of our customers are repeat buyers.

TPI: To what extent has your product portfolio expanded over the years? How are you catering to the steel tubes & pipes segment?

RKG: Hariom Pipe Industries Limited has a diverse product portfolio that includes premium and value-added products. We started with mild steel (MS) billets and since then, have been continuously value-adding our offering, which now consists of hot rolled (HR) coils, cold rolled (CR) coils, MS tubes and pipes, HR pipes and tubes, CR pipes, pre-galvanized (GP) coils, GP pipes and GI pipes for circular, square and rectangular sections, along with scaffolding systems. A prime example is the addition of a tandem mill, which gives us the flexibility of meeting exacting customer requirements in rolling our thinner sections without compromising on tensile strength. The company manufactures HR and CR pipes in sizes up to 150×150mm for square sections, 200x100mm for rectangular sections and 175 NB for circular sections, with thickness ranging from 0.40mm to 6mm across the range of products, including GP/GI pipes. Our diverse steel products drive progress across industrial, construction and domestic sectors, underscoring our commitment to craftsmanship and reinforcing our fierce focus on customer delight.

TPI: Discuss your infrastructure set-up and production capabilities.

RKG: We have four manufacturing facilities with a total capacity of 7,01,232 MTPA of steel (including 2,64,232 MT for backward integration). Backward integration ensures superlative input quality (sponge iron facility in Anantapur, Andhra Pradesh) and forward integration (secondary steel manufacturing facility in Perundurai, Erode, Tamil Nadu). We are the first company in India to run our pipe manufacturing operations entirely on renewable energy in Telangana. Our integrated steel plant in Mahbubnagar district of Telangana comprises a melting shop and two cutting-edge steel manufacturing units for the production of galvanized pipes & coils. We have recently commissioned a state-of-the-art CR tandem mill at our Mahabubnagar plant, producing high-quality pipes with minimal thickness variation. This has enabled the production of pipes with thicknesses as low as 0.4mm, which are high in demand and command premium prices. We increased our pipe mill’s capacity by 1,32,000 MTPA and total capacity by 1,68,000 KT in FY24. Our commitment to expanding value-added products share resulted in a record high of 98 percent for FY24.

TPI: What strategies do you employ to maintain brand visibility and stay ahead of the curve?

RKG: Hariom Pipes has established a formidable brand strategy centered around three core pillars: quality, service, and customer satisfaction. Our commitment to providing high-quality products ensures that our customers only get the best products. We understand the importance of customer satisfaction, which is why “Just in Time” product delivery is our abiding mantra, irrespective of volume ordered.

Our advertising & promotional approach integrates both traditional (wall painting, backlit signages etc) and digital marketing channels (social media), allowing us to reach a broader audience and enhance our brand visibility. Since we are primarily B2B, we effectively engage with our dealers/retailers & whole-sellers and of course the OEM segment, besides our own warehouses, to stay ahead of the curve. My senior management team also meets customers on a personalized basis, periodically and appraises them with our new product offerings. This is in addition to my sales team’s transactional sales call/visits. The idea is to continually engage with them because we believe that they are central to our success.

In terms of maintaining a competitive advantage, our manufacturing capabilities are all state-of-the-art and planned investments are scheduled to ensure that we walk the talk. Strategically-located facilities further complement our efforts, allowing us to efficiently serve diverse geographical markets. Our focus on high-margin, value-added products enables us to offer solutions, not just merely “sell” our products.

Our ability to customize products in terms of thickness, length and quality plays a crucial role in maintaining “Edge over Others,” giving clients exactly what they need for their specific applications.

By staying true to our core values and continuously adapting to industry trends, Hariom Pipe Industries Limited is not only meeting but exceeding customer expectations, establishing a legacy of excellence that will last for generations. That’s my wish list and that is what is very dear to my heart.

Also Read: Vibhor Steel Tubes Eyeing Infrastructure Market with New Odisha Plant

TPI: How important is sustainability to your company’s identity, and what steps do you take to uphold it?

RKG: At Hariom, we have embarked on a journey to be a benchmark for ESG for mills of our size. We are putting in processes to measure absolute emissions, Scope 2 and Scope 3, besides following GHG norms for conservation of groundwater and recycle/conserve water/waste and aiming to be net zero. We recognize the critical importance of nurturing a safe, pristine environment and protecting the ecosystems that support us. Our focus is on reducing emissions, managing water resources efficiently and minimizing waste generation. We have implemented several significant environmental initiatives, including recycling 34,000 metric tons of steel, which significantly contributes to our sustainability goals. Additionally, we have reduced carbon emissions through the implementation of hot charging technology and achieved zero liquid discharge (ZLD), ensuring that we manage our resources responsibly.

One of our pioneering efforts is the establishment of India’s first pipe unit powered entirely by solar energy, reflecting our commitment to renewable energy sources. Furthermore, our raw material strategy incorporates a 30 percent share of steel scrap, significantly reducing the environmental impact of our operations.

In fiscal year 2024, we achieved key sustainability milestones, notably by transitioning our GP plant at Mahabubnagar, Telangana completely to solar power, which has substantially reduced carbon emissions. This transition underscores our dedication to a greener future.

At our Perundurai plant in Tamil Nadu, we are ushering in a new era of green energy through our innovative biogas fuel initiative. Supported by Indian Oil, this clean gas option will propel our operations with significantly lower emissions compared to conventional industrial fuels. This initiative exemplifies our commitment to sustainable innovation and our proactive approach to reducing environmental footprints across all our operations. These efforts collectively highlight our unwavering commitment to a sustainable future and our proactive initiatives in promoting green technologies and practices within the industry.

We are the first company in India to run our pipe manufacturing operations entirely on renewable energy.

TPI: What is your company’s vision over the next five years and how will you realize this vision?

RKG: Hariom Pipes aims to achieve robust and sustainable growth by focusing on our six foundational strategic pillars, which are designed to drive profitability, enhance customer experience and ensure inclusive growth for all stakeholders. Our overarching goal is to fully leverage our current installed capacity by 2026, asserting our ambition to cement our growth position in the industry.

Our strategy involves not just surviving but thriving, as Hariom Pipes embarks on a visionary path towards sustained and meteoric growth. Central to this journey is our commitment to sustainable expansion, characterized by a broader geographical presence and an enriched value-added product portfolio. By doing so, we aim to capture untapped markets, cater to emerging customer needs and deliver superior products.

We are steadfast in ensuring that this growth positively impacts all involved. Our strategic direction is informed by a commitment to inclusivity, making certain that every stakeholder reaps the benefits of our progress. This includes shareholders, employees, customers and the communities in which we operate.

By adhering to this comprehensive growth strategy, Hariom Pipes is poised to achieve and sustain industry leadership. We look forward to the challenges and opportunities ahead, ensuring that our expansion is not only profitable but also sustainable, creating long-lasting value for all stakeholders involved. Together, we will forge a future of shared success, setting new benchmarks for excellence in the industry.