From precision tube mills and automated bending systems to sustainable handling solutions and Industry 4.0 integration, global and Indian technology leaders are redefining how tubes and pipes are manufactured, finished, and delivered.

The Backbone of Modern Infrastructure

Tubes and pipes are present everywhere, despite their infrequent recognition. They carry oil and natural gas across continents, transport clean drinking water to homes, circulate fluids in power plants, frame skyscrapers, strengthen bridges, and form the invisible veins of automobiles and aircraft. They’re also playing an increasing role in renewable energy. Sturdy, precisely-made tubes and pipes are vital for solar setups, wind turbines, and hydrogen lines.

In India, the demand for these products is not only rising but diversifying. Due to rapid urbanization, major infrastructure projects, growing oil/gas networks, and the expansion of the automotive and white goods industries, India has become a leading hub for tube and pipe production. This growth is mirrored globally, where infrastructure renewal in developed economies and industrial expansion in emerging regions keep demand high.

However, success isn’t solely defined by scale. Modern manufacturers face pressure to boost output, speed, and precision, while staying affordable and eco-friendly. Technology and machinery are key to finding this balance. Modern tube and pipe plants are no longer just lines of rolling machines; they are integrated ecosystems of mills, finishing systems, bending machines, robotics, testing benches, and automated handling equipment, each playing a critical role.

“The tube and pipe industry has experienced remarkable growth,” emphasizes Arth Shah, Executive Director of Parth Equipment. “Today, steel pipes have become essential across numerous sectors, including construction, modern infrastructure, agriculture, furniture, automotive, oil and gas, and many other sectors.” His words highlight an essential truth: the progress of this industry is inseparable from the machinery that powers it.

To meet the demands of sustainable production with scale and precision, manufacturers worldwide (from legacy firms to agile startups) are reimagining the machinery that produces, shapes, finishes, and delivers tubes and pipes. Tube & Pipe India traces this transformation, showing how smarter mills and sustainable machinery are powering the future of the Indian tube and pipe industry.

Tube Mills and End-to-End Production Systems

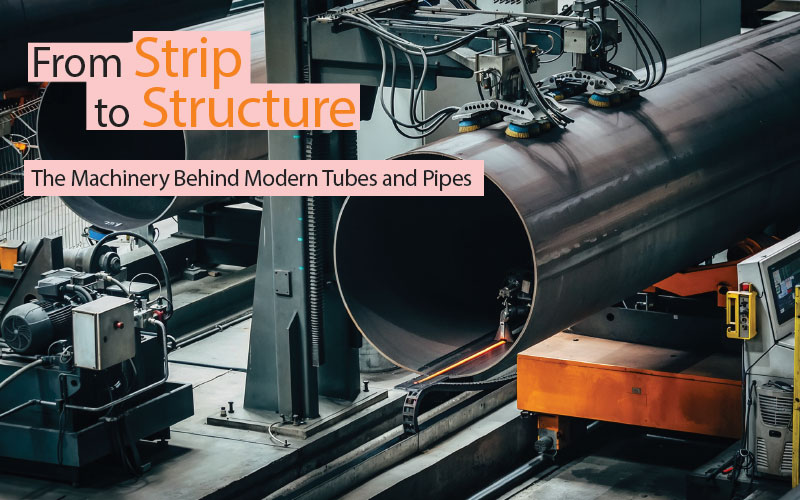

At the heart of tube manufacturing lies the tube mill. Whether for producing mild steel, stainless steel, or non-ferrous tubes, tube mills represent the starting point where flat strips of metal are shaped, welded, sized, and finished into circular, square, or rectangular profiles.

Traditionally, electric resistance welded (ERW) tube mills have dominated the landscape, owing to their efficiency in producing high-quality welded pipes. Here, strips of metal are gradually formed into a cylindrical shape using a series of rollers, after which the edges are welded using high-frequency current. Precision at every stage, i.e., forming, welding, sizing, and straightening is critical, as even minor misalignment can affect tube integrity.

In India, Ananta Engineering, part of the Ananta Group, has positioned itself as a turnkey solutions provider in this space. Founded in 2006, the company has grown from a promising enterprise into a global player serving both domestic and international markets. Pawan Singh, Managing Director of Ananta Group, says, “We offer a comprehensive range of high-performance machinery for the tube and pipe industry.” The company makes a wide range of solutions, from ERW tube mills and finishing systems like flying cold saws, end-facing, and bundling units, to coil processing lines such as slitters, cut-to-length setups, and hydraulic decoilers. Its portfolio also extends to roll forming machines for purlins, roofing sheets, and crimping, along with auxiliary equipment including gang slitters, chain link machines, and specialized roll tooling.

Turnkey capability is critical in today’s market. Manufacturers do not simply want machines; they want integrated production ecosystems that can seamlessly deliver output while minimizing downtime. Ananta has built its reputation on this approach, delivering fully integrated plants, complete with installation, commissioning, and after-sales support.

“Each product line is engineered for turnkey implementation, right from design and manufacturing to installation, commissioning, and after-sales service,” adds Pawan Singh. This holistic service model has been a differentiator in global markets, particularly in regions like Southeast Asia, the Middle East, and Africa.

GMT Industries, another Indian leader, echoes this trend with its strong emphasis on end-to-end production systems. Established in 2008, GMT has become synonymous with ERW tube mills and finishing line equipment. The homegrown leader has taken a step further by pioneering Direct Forming Technology (DFT).

“DFT tube mills bring enhanced precision and efficiency to the tube manufacturing process by allowing for direct forming without the need for roll changes, thereby reducing downtime and improving productivity,” explains Neeraj Dubey, Managing Director of GMT Industries. By DFT, GMT has pushed the boundaries of flexibility, allowing manufacturers to switch between different tube profiles without time-consuming tooling changes.

The company’s expansion into large-diameter tube mills, 16-inch and 20-inch capacities, further illustrates how equipment suppliers are catering to evolving market needs. With applications ranging from structural projects to energy transmission, large-diameter pipes are increasingly in demand, and machinery capable of producing them with speed and precision is becoming indispensable.

Meanwhile, Parth Equipment, founded in 1988, continues to bridge the spectrum from ferrous to non-ferrous tube manufacturing. With over 75 models across 15 categories, Parth has developed a diversified product basket ranging from stainless steel and carbon steel tube mills to polishing, hydrotesting, coil slitting, and tube-end chamfering machines. This wide scope ensures that the company remains resilient even during market fluctuations.

“We are one of the few manufacturers to supply a complete range of equipment for the tube and pipe industry,” notes Arth Shah. This diversity has helped Parth penetrate global markets, supplying plants to leading names across India, the USA, the Middle East, and Africa.

These players show a key shift: the industry now values complete solutions over individual machinery, with efficiency and versatility as the key to success.

Precision, Bending, and Automation

After tubes are produced, many applications require them to be bent, curved, or shaped into precise geometries. This is particularly vital in automotive, aerospace, HVAC, and furniture sectors, where millimeter-level precision can determine both performance and safety.

For decades, hydraulic bending machines dominated this space, but they came with inherent limitations. Variations in oil temperature could alter viscosity and affect bending accuracy. Changeovers between batches were time-consuming, requiring manual adjustments. Energy consumption was high, as hydraulic pumps ran continuously even when idle.

Enter full-electric CNC-driven bending machines, pioneered by companies like Crippa of Italy. “In terms of energy usage, our full-electric machines consume just 10% of the energy required by their hydraulic counterparts,” notes Carlo Fratini, Business Development Manager at Crippa. “Unlike hydraulic pumps that run continuously, our motors only consume power when in operation —making our systems not just greener, but also more cost-effective.”

Beyond energy efficiency, CNC control ensures repeatable accuracy, with automated axes controlling mandrel positioning, clamping torque, and slide settings. Operators can store and recall setup parameters, eliminating the need for repeated manual adjustments. The result is faster changeovers, reduced scrap, and enhanced production throughput.

Automation has further elevated bending technology. Robotic integration, from material loading to finished part unloading, minimizes human error and labor dependence. “…labor shortages and rising costs have driven demand for robotic integration — particularly in the automotive industry,” Fratini explains. “Crippa offers fully automated, robot-assisted production cells, helping customers reduce in-process inventory and achieve finished components directly from raw material inputs.”

Indian manufacturers, too, are embracing automation. Parth Equipment has embedded SCADA and Industry 4.0 features into its machines, enabling real-time monitoring of OEE (Overall Equipment Efficiency), predictive maintenance alerts, and autonomous reporting. “We are continuously adding new automation features to our machines to increase productivity and reduce manpower,” Arth Shah emphasizes.

This blend of precision, automation, and digitalization indicates where the industry is headed. Production systems are evaluated on both durability and their capacity to incorporate intelligence and sustainability.

Finishing, Testing, and Handling

The production of a tube or pipe does not end once it leaves the mill or bending machine. In many ways, the more critical processes begin afterward. Straightening, finishing, hydrotesting, pointing, swaging, and handling all ensure that tubes are fit for demanding end-use conditions.

JAROS Industries, founded in 1985, has become synonymous with this stage of production. With over 40 years of experience, the company has developed a strong reputation for tube straightening machines, swaging systems, push pointing equipment, and hydrotesting benches. In 2024, it achieved a milestone by delivering India’s first automatic heavy-duty drawbench.

“…we marked a major milestone in innovation by successfully manufacturing and commissioning India’s first automatic heavy-duty drawbench with a 250-tonne pulling load capacity that seamlessly integrated with in-line pointing and straightening units—all within a single automated system,” recounts K.J. James, Founder & Director of JAROS.

Hydrotesting is especially crucial. Every tube intended for high-pressure applications, such as oil pipelines, boilers, or nuclear plants, must undergo rigorous testing to ensure there are no leaks or weaknesses. JAROS’s high-pressure benches meet global standards like API, ASTM, and IS, ensuring compliance for international exports.

Handling, often overlooked, is another vital piece of the puzzle. Tubes and pipes are typically long, heavy, and unwieldy, making their storage and transportation a logistical challenge. Mishandling not only risks worker safety but can also damage products, leading to costly rejections.

This is where Combilift, based in Ireland, has established a global niche. Its multidirectional forklifts, sideloaders, and straddle carriers are purpose-built for handling long and bulky loads. “The multidirectional capability allows for sideways navigation while handling long and bulky loads of tubes or pipes… significantly reducing the risk of injury or collision,” explained Martin McVicar, CEO & MD of Combilift.

What makes Combilift’s solutions particularly relevant is their adaptability to tight spaces. By enabling navigation through narrow aisles and maximizing vertical storage, these machines reduce the warehouse footprint required, a significant cost advantage for manufacturers. Moreover, with 70% of Combilift’s production already electric, the handling process itself aligns with the sustainability goals of modern manufacturing plants.

Together, finishing and handling machinery ensure that tubes and pipes are not only manufactured to specification but are also delivered safely, tested rigorously, and stored efficiently. Without them, the promise of precision at the mill or bender would remain incomplete.

Also Read: GMT Industries Targets INR 500 Crore Revenue with New Palwal Plant Expansion

Manufacturing Sustainability, a Core Talk

The conversation in industrial manufacturing is shifting irreversibly toward sustainability, and the tube and pipe machinery segment is no exception. From reducing energy consumption to integrating renewable power and minimizing waste, equipment suppliers are embedding green thinking into every process.

Combilift leads this charge with electric-powered handling solutions. “Sustainability is at our core – we’re highly focused on making our vehicles more environmentally friendly and helping our customers maximise their warehouse efficiency,” McVicar emphasized. Recent launches like the Combi CB70E, Combi-Cube, and Combi-AGT highlight this shift, with more than 70 percent of Combilift’s current output already running on electric power.

These innovations not only expand the company’s product range but also support its sustainability goals, cutting emissions, reducing environmental impact, and helping customers optimise warehouse space for greater energy efficiency. The company has even redesigned its facilities with solar panels, rainwater harvesting, and natural lighting, demonstrating that sustainability must permeate both products and operations.

“Crippa transitioned to full-electric technology more than a decade ago, which was a major step toward sustainability,” informs Carlo Fratini. By shifting entirely to full-electric bending systems, Crippa has eliminated the use of hydraulic oil and its associated waste, while slashing energy consumption to a fraction of traditional machines. This transition not only delivers precision and cost savings but also strengthens the company’s commitment to greener, more resource-efficient manufacturing.

Parth has embedded sustainability into its operations by installing solar power plants at its manufacturing facilities and integrating energy-efficient drives into its machines. These measures reduce the company’s carbon footprint while ensuring customers benefit from lower operating costs and reliable, eco-conscious technology.

At Ananta, ongoing R&D investments in automation and energy-efficient systems are tied directly to sustainability objectives. By integrating advanced drives and IoT-enabled monitoring, the company enables clients to cut energy use and improve plant efficiency, contributing to a leaner, more sustainable production ecosystem. “We continue to innovate in product development to support sustainability and energy efficiency,” adds Pawan Singh.

JAROS combines its focus on heavy-duty, high-precision equipment with sustainable practices such as optimized hydraulics, servo technology, and waste-reduction systems. These advances enhance machine performance while ensuring responsible use of energy and resources across its finishing solutions.

But sustainability is not just about the environment. It is also about building resilient supply chains. With global shifts away from Chinese dominance, India has emerged as a strong alternative manufacturing hub. As K.J. James pointed out, “The future belongs to those who combine engineering excellence with automation and global agility. And that’s exactly where JAROS is heading for.”

Looking ahead, the road for the tube and pipe machinery industry is paved with opportunities. Infrastructure booms in Asia, Africa, and the Middle East will drive demand. Renewable energy, hydrogen transmission, and smart water systems will create entirely new applications. Advanced technologies like Direct Forming Technology, robotic integration, predictive analytics, and modular production lines will set new benchmarks.