Crippa is a global provider of advanced tube bending solutions, capable of processing steel tubes ranging from 4 mm to 225 mm in diameter. The company delivers fully-automated, robot-assisted production cells. In an exclusive interview with Tube & Pipe India, Mr. Carlo Fratini, Business Development Manager at Crippa, shared that the group currently has a combined turnover of EUR 95 million and operates in over 80 countries. Going forward, Crippa aims to achieve a turnover of EUR 130 million by 2028, positioning itself as a one-stop solution provider for HVAC manufacturers worldwide.

Tube & Pipe India: How has the adoption of electric and CNC-driven tube bending machines influenced market dynamics and brought competitive advantages within the tube and pipe manufacturing industry?

Carlo Fratini: The introduction of full-electric and CNC-driven tube bending machines has significantly transformed the tube and pipe manufacturing industry. One of the key advantages is the drastic reduction in changeover time. Operators can store and recall custom setup parameters—including mandrel and clamp positioning, clamping torque, and slide settings—eliminating the need for manual adjustments between batches. This results in substantial time and material savings.

Precision is another major benefit for the tube and pipe machineries. In hydraulic systems, performance can fluctuate with oil temperature changes, which affect viscosity and, ultimately, bending accuracy. Full-electric machines eliminate this variable by using CNC-controlled axes that maintain consistent positioning, ensuring superior precision and repeatability in every production cycle.

TPI: What is your current market share in the tube and pipe bending machine segment, and how do you plan to increase it?

CF: Globally, we rank among the top three manufacturers of tube and pipe bending machines in terms of revenue. We maintain a strong presence in Western markets, while our position in Eastern and far Eastern regions is still developing.

To expand our market share, we are focusing on cost-sensitive solutions and exploring opportunities to localize manufacturing, which will allow us to offer more competitively priced machines in emerging markets.

TPI: Please provide a brief overview of the company?

CF: Crippa is part of the OCTA Group, which includes three leading brands: Crippa, SMI, and CMS.

Founded in 1948, Crippa was the first company in Europe to design and manufacture machines for bending metal tubes. It quickly experienced exponential growth, both nationally and internationally, eventually becoming a major player in tube shaping as well.

Established in the late 1970s, SMI quickly became a reference point for HVACR and automotive companies that needed to work with metal tubes and alloys, including coils.

CMS is the youngest company in the group. It specializes in designing and building presses and molds for the production of finned packs. Its rapid and steady growth has earned it a prominent position among international manufacturers in the sector.

The group has a combined turnover of EUR 95 million and operates in over 80 countries through a mix of direct sales and a robust network of trained representatives. We employ more than 300 professionals across three production facilities located in Carugo (near Milan), Vicenza (near Venice), and Varmo (near Udine).

‘‘The OCTA Group is the only global supplier capable of serving top-tier HVAC brands from start to finish—providing fin presses, hairpin benders, and CNC bending machines for inlet and outlet pipelines.’’

TPI: Please tell us about your portfolio and how it serves the tube and pipe industry.

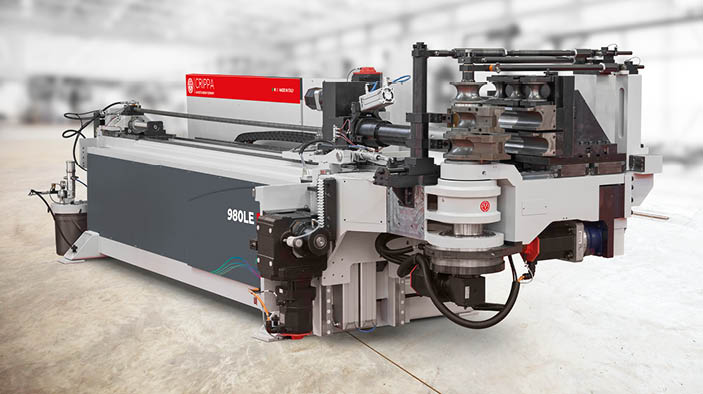

CF: We are the only company globally offering tube bending solutions capable of processing steel tubes ranging from 4 mm to 225 mm in diameter. Our portfolio includes right-left, multi-level, multi-radius, and fully electric bending machines. We are proud to provide precision, flexibility, and repeatability, delivering highly competitive solutions to a broad range of industrial sectors.

TPI: What is your brand’s USP that sets you apart from the competition? Why do tube and pipe manufacturers prefer your products?

CF: Crippa machines are renowned for their robustness, precision, speed, and repeatability. Whether it’s the high accuracy demanded by aerospace applications, the volume requirements of the automotive sector, or the flexibility needed in furniture manufacturing—Crippa consistently delivers. Our ability to tailor machines to these diverse needs is a core reason manufacturers choose us.

TPI: Tell us about your market presence and key clientele. How do you cater to various sectors within the tube and pipe industry?

CF: While specific client names are protected by NDAs, we can share that we have over 20 machines installed at one of India’s largest automotive component suppliers, and we recently secured a contract with a leading aircraft engine manufacturer in the region.

Crippa has significantly diversified its solutions over recent years, adapting technology to new sectors such as HVAC. The OCTA Group is the only global supplier capable of serving top-tier HVAC brands from start to finish—providing fin presses, hairpin benders, and CNC bending machines for inlet and outlet pipelines.

Wherever cooling systems are used—whether in cars, buildings, or commercial centers—you’ll likely find an OCTA Group production line behind it.

‘‘We were the first to develop a right- and left-handed bending machine, as well as the first to introduce a fully electric solution.’’

TPI: How do you ensure power efficiency and sustainability in your machines? How do you support green manufacturing?

CF: Crippa transitioned to full-electric technology more than a decade ago, which was a major step toward sustainability. Our machines no longer require hydraulic oil, eliminating the need for regular oil changes and the management of hazardous waste. In terms of energy usage, our full-electric machines consume just 10% of the energy required by their hydraulic counterparts. Unlike hydraulic pumps that run continuously, our motors only consume power when in operation—making our systems not just greener, but also more cost-effective.

TPI: How have Industry 4.0 technologies, robotics integration, and automation impacted the tube and pipe machinery segment? Do you integrate these into your products?

CF: Industry 4.0 has become integral to our product offerings. Our customers demand both simple and advanced data insights—from cycle times and batch tracking to axis diagnostics and predictive maintenance indicators such as vibration metrics. To meet these needs, we have developed advanced software packages that can be bundled with our machines.

In terms of automation, labor shortages and rising costs have driven demand for robotic integration—particularly in the automotive industry. Crippa offers fully automated, robot-assisted production cells, helping customers reduce in-process inventory and achieve finished components directly from raw material inputs. This not only streamlines operations but also enhances overall efficiency and consistency.

TPI: What is the current scenario of the tube and pipe segment? How will you contribute to the growth and innovation of this sector?

CF: The tube and pipe bending sector faced a challenging year in 2024 due to the increasing electrification of vehicles and various emerging geopolitical issues. However, 2025 has begun on a more positive note, with an average increase of 10% in tube bending consumption observed so far.

In terms of innovation, Crippa has always been at the forefront of technological advancement. We were the first to develop a right- and left-handed bending machine, as well as the first to introduce a fully electric solution.

Looking ahead, we are working closely with our customers to explore new methods to accelerate production processes and improve overall efficiency, ensuring we continue to lead in innovation within the sector.

Also Read: Shri Bhagwati Machines: Powering Precision Through Next-Gen Tube Laser Cutting and Automation

TPI: What are your future plans for the next 5–10 years, leading to the growth of your company?

CF: According to our current business plan, we aim to reach a turnover of EUR 130 million by 2028. This growth will be driven primarily by our unique position in the market as the only group capable of offering a true one-stop solution for all global HVAC players. The HVAC segment represents a key strategic focus for us, and we believe the comprehensive solutions we provide will play a pivotal role in our expansion over the coming years.

‘‘We have over 20 machines installed at one of India’s largest automotive component suppliers, and have recently secured a contract with a leading aircraft engine manufacturer in the region.’’