GL Control GmbH, a subsidiary of GL Messtechnik GmbH, has specialised in the development, production and distribution of laser-based profile measuring systems in its origins for almost 30 years. GL Control GmbH has become the true partner for precise and non-contact measuring solutions for laser-based capture of internal geometries of tubes and other hollow bodies.

The history of GL Control GmbH dates back to 1993, when Dr. Noll founded a company for customers in the tire industry by the name of Dr. Noll GmbH to measure tire profiles through laser. His measurement systems were soon used by tire manufacturers, test institutes and car producers worldwide. After reaching the numero uno spot in the tire industry, Dr. Noll founded the GL Messtechnik GmbH in 2015 and expanded into the automotive & tube industries with new developments. In 2023, the subsidiary GL Control GmbH was founded, to concentrate on the development of laser technology for pipeline inspection. Tube manufacturers and testing labs have gained immense success by using the technology of GL Control GmbH.

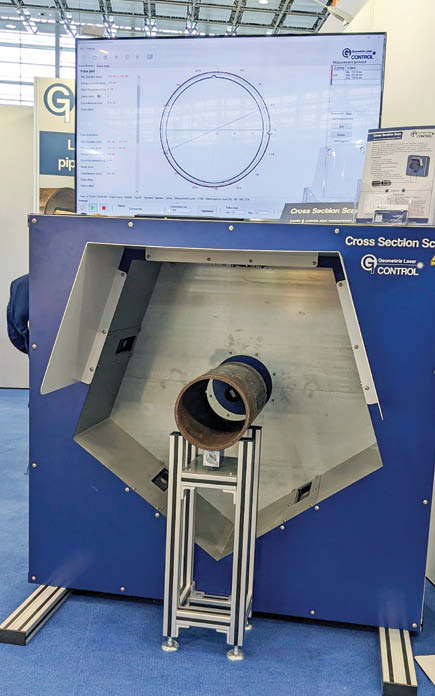

The Cross Section Scan (CSS) is a laser triangulation-based advanced quality control solution offered by GL Control, Germany, which enables pipe manufactures to inspect and analyse the cross-sectional profiles: dimensions, wall thickness and surface quality of pipe ends with exceptional accuracy. The CSS can inspect a variety of pipe materials and is available in different models depending on size range to cover a total range of OD 100mm-1000mm.

The circular triangulation sensor, also known as CiTriS, is used from the inside and line sensors from the outside. Together, this results in a high-resolution 3D point cloud of the entire pipe. The measured values can be used to determine the inside and outside diameter, thickness, and analyse the weld seam of the pipe.

The geometry values can also be used to determine the out of roundness. In the view, engineers can thus identify weak points in the pipe geometry using pseudo colour images.

Also Read: Inspectech Analygas: Online System for Quality Monitoring of ID Scarfing of Welded Pipes

A tolerance for the operator can be specified within the software. If the measured values are outside the tolerance range, the software issues a red signal. If the measured values are within the measuring range, it lights up green. Outputs are provided that could be used for visual, audio and spray markers.

The data can be saved as .csv (measurement values), .pdf (false colour picture or measurement values) or .stl (3D model).

It is also possible to inspect the surface for damaged areas or defects when applying an epoxy resin layer of the inside. The CSS can be customised in various ways to be integrated into the production line.

GL Control also offers robotic full pipe length ID dimensional measurement using their Robotic ID crawler.