InspecTech Analygas has been a leader in customizing non-destructive testing (NDT) solutions. In addition to their in-house electrical and mechanical engineers, the company has software and firmware specialists. Its InspecTech B-Scan Inspection System (IBIS) is an ultrasonic device, which is specially useful to the welded tube industry. It scans the weld zone and monitors the quality of the flash removal process.

Company Profile

InspecTech has been in business since 1977 customizing NDT solutions utilizing the eddy current, flux leakage, and ultrasonic technologies. It takes a look at the customer’s application and the specifications needed to be met, then recommends the best technology. InspecTech’s objective is to supply engineered solutions to NDT problems by providing innovative and rugged test systems, fully integrated into the production environment. InspecTech manufactures all mechanics, and electronics, and develops our own software in-house. For 15 years, InspecTech has designed and supplied sophisticated in-service inspection pigs that use the flux leakage technique to gather high-resolution data from oil and gas transmission pipelines.

Market Footprint

Inspectech is currently present in the oil & gas industry and automotive industry. It also provides structural and turnkey solutions. InspecTech owns 50 percent market share of the NDT business in the U.S. and 80 percent in Mexico. The company added seven new representatives in South America, Europe as well as Chengdu, China. Our global network is spread across the globe, including Asia Pacific, Canada, Europe, Latin America, Russia, South America, and the United States of America. Some of our major clients are Tenaris, Tejas, Peasa, Tenneco, Chung-Hung Steel, American Cast Iron Co., Forza, Canadian Phoenix, and Thyssenkrupp.

Product Portfolio

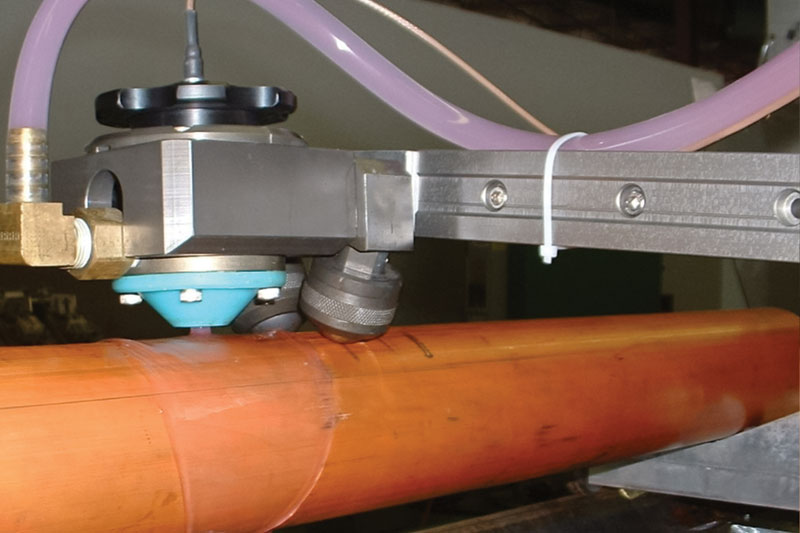

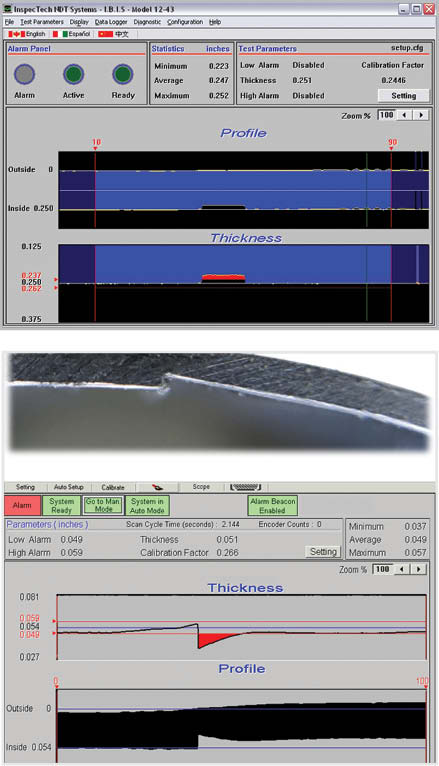

We have a diverse range of products in our portfolio. Eddy current full body, eddy current weld line, offline & online ultrasonic testing, and ultrasonic skelp monitoring system are some of our products. We are the proud manufacturers of the IBIS Scarf Monitoring System. The InspecTech I.B.I.S. (InspecTech B-Scan Inspection System) is an ultrasonic device, which is specially useful to the welded tube industry. It scans the weld zone and monitors the quality of the flash removal process. Its key features are:

- Scrap Reduction – Catches flash removal problems before they become costly.

- Real-time presentation of wall thickness data in engineering units over the weld.

- Audio and visual alarms for high and low limits of wall thickness.

- “Hands Free” unattended operation.

- Complete data logging of all online test parameters easily stored, retrieved, hard-copied or downloaded.

- Instant recall of previously used setups.

- Weight calculation and cutting to weight (optional).

The InspecTech I.B.I.S. is primarily a scrap reduction tool. It displays the weld profile in engineering units and in real-time on a video display. Broken, worn, or chipped flash-cutting tools or mismatched weld edges are easily detected and alarmed. It also monitors the weld profile to make sure that the overall weld thickness is within tolerance.

Also Read: Shanghai Ultrabest: Manufacturing Advanced Ultrasonic NDT Inspection Systems for Pipes & Tubes

Besides, we offer the Magnetic Flux Leakage (MFL) system, which can test welded steel blanks up to 3mm thick. While MFL is one of the oldest NDT methods, its utilization to test laser weld seams in carbon steel tailored blanks is relatively new. In InspecTech MFL, testing is done by passing the material seam over the test head on a conveyor, or by passing the test head over the part by robotic manipulation.

Research and Development

InspecTech’s research and development team works closely with our clients, towards a goal of continuous improvement to our equipment and systems. For example, the use of flux leakage testing for ERW long seams is rapidly gaining international acceptance. With many years of experience in NDT systems, InspecTech exercises continuous improvement policies, to supply the welded tube industry with systems of the highest reliability and sophistication, coupled with ease of understanding and operation.