Founded in 2016, Insta Pressfit® has transformed the stainless-steel piping industry with its innovative, hygienic, durable, and installation-friendly solutions. By 2023, the company secured a strategic partnership with Hisar Metal Industries Limited, enabling it to expand its product portfolio and strengthen its foothold in the commercial market segment. In an exclusive interview with Tube & Pipe India, Mr. Nimit Varshney, Founder & CEO, Insta Pressfit® shares insights into how Insta Pressfit® stands out by leveraging cutting-edge technology, rigorous research and development, and industry-leading standards to ensure the highest quality and reliability in its offerings.

Tube & Pipe India: How would you describe your company’s journey since its establishment? What elements have played a significant role in the success of this journey?

Nimit Varshney: Founded in 2016, Insta Pressfit® was born out of a shared vision to revolutionize the stainless-steel pipe industry to provide innovative, hygienic, long lasting and installation friendly piping solutions.

With only a small team and limited funding, the early years were marked by significant hurdles, from building initial products to gaining market traction.

In 2016, Insta Pressfit® launched India’s first stainless steel food grade pipe, which quickly gained traction in the household plumbing market. The next years saw rapid growth, expanding our client base across pan India. By 2023, we secured a strategic partnership with Hisar Metal Industries Limited, which allowed us to expand our product in the commercial market segment.

TPI: Can you walk us through your journey in the stainless-steel tubes & pipes segment?

NV: We started our journey with basic stainless steel food grade pipes and fittings and over time, evolved to offer a wide range of specialized products, including precision-engineered fittings, high performance food grade pipe and custom finishes. This expansion has been driven by market demands for more advanced and reliable plumbing solutions, particularly in industries such as household, commercial buildings, hospitals and restaurants.

Our ability to adapt to market shifts has played a key role. For example, when many households and commercial buildings including hospitals were struggling with the problem of scaling and rusting of normally used CPVC pipes, Insta Pressfit® was able to provide the solution to scaling and rusting, ensuring both hygienic and long-lasting food grade pipes.

Our success in this segment is rooted in our investment in cutting-edge technology, continuous R&D, and a deep commitment to delivering high-quality plumbing solutions. By understanding the specific needs of our clients and providing customizations such as tailored lengths, specialized finishes and innovative plumbing solutions, we have built strong relationships and established ourselves as a trusted manufacturer and supplier of stainless-steel pipes and fittings.

TPI: How has the association with Hisar Metal Industries helped you in your growth?

NV: One of the most important factors in our success has been our commitment to innovation. By partnering with Hisar Metal Industries Limited and investing heavily in research and development, Insta Pressfit® has been able to introduce pipes and fittings that not only meet market needs but also set new industry standards.

Our strategic partnership with Hisar Metal Industries Limited has expanded our reach and capabilities, and our focus on a customer-centric approach that has helped build a loyal base. Financial prudence, coupled with a strong, collaborative company culture, has enabled us to navigate challenges and seize growth opportunities. All these elements, working together, have been instrumental in our journey.

TPI: In what ways do your stainless-steel offerings stand out from those of your competitors?

NV: Our stainless-steel food grade pipe and fittings offerings stand out in several key areas, making us a preferred choice for many segments.

First and foremost, we pride ourselves on the superior quality of our pipes and fittings. We use only high-grade stainless-steel alloys, ensuring exceptional resistance to corrosion and wear, which is critical for demanding applications in industries like household plumbing, hospitals etc. Our products also adhere to industry-leading standards, offering our customers confidence in both quality and reliability.

Additionally, our extensive customization options set us apart. We offer tailored solutions, including custom dimensions, surface finishes to meet the unique needs of each customer. This level of flexibility allows us to serve a wide range of industries, from household to hospitality and health care, with products that perfectly align with their specific requirements.

Through continuous research and development, we have introduced new technologies and coatings that enhance the performance and durability of our stainless-steel pipes and fittings. We are also focused on providing outstanding customer service, with expert sales/engineers available to provide technical support and guidance throughout the entire project lifecycle.

Finally, our competitive pricing, quick turnaround times, and commitment to sustainability make our stainless-steel pipes and fittings a superior choice in the market. Whether it’s through eco-friendly manufacturing processes, we ensure that our customers are getting the best value while also supporting environmentally responsible practices.

TPI: What special technologies are used to manufacture the SS product lines?

NV: Some of the special technologies used in the manufacturing of our SS product line include advanced manufacturing techniques, automation and precision, coating and finishing technologies, heat treatment and annealing, and lastly testing and inspection technologies.

Our stainless steel product lines are manufactured using a combination of cutting-edge technologies, ensuring high-quality, durable and precise products. We also utilize advanced coating and finishing techniques such as passivation and electropolishing to improve corrosion resistance and enhance the aesthetic appeal of our pipes. Furthermore, our heat treatment processes including controlled annealing that help us improve the mechanical properties of our stainless steel pipes, ensuring they meet the specific requirements of critical applications in harsh environments.

TPI: Discuss about the infrastructure set up and your production capabilities for this segment.

NV: Our production capabilities are backed by a highly advanced infrastructural unit of Hisar Metal Industries Limited capable of handling both large-volume and custom orders. The facility is outfitted with state-of-the-art equipment such as high-precision CNC machines, automatic tube mills, draw benches, and pilger mills which enables us to produce a wide range of stainless steel pipes with various diameters, thicknesses and custom lengths.

We have an annual production capacity of over 1000 tonnes of stainless steel pipes, with the flexibility to scale up or down based on customer demand.

Hisar Metal Industries Limited manufacturing unit is designed keeping automation in mind, incorporating robotic systems for material handling, reducing human intervention, and enhancing efficiency. Additionally, the company follows lean manufacturing principles, ensuring reduced lead times and minimized waste throughout the production process.

TPI: Can you tell us about your quality control and testing infrastructure?

NV: Quality control is a core aspect of our manufacturing process, and Hisar Metal Industries Limited utilizes advanced testing equipment to ensure the highest standards of product reliability and performance. All our stainless steel pipes undergo rigorous dimensional checks using automated measurement systems that ensure compliance with precise tolerances. Additionally, all pipes are subjected to mechanical and corrosion resistance tests to ensure they meet the required industry standards.

Other testing and inspection measures incorporated by the company for ensuring the quality and reliability of the stainless steel products include Non-Destructive Testing (NDT), dimensional and surface quality check, and certification and compliance.

Hisar Metal Industries Limited manufacturing process is fully compliant with ISI 6911:201 for coil manufacturing and ISO 14001:.2015 certifications, guaranteeing that our pipes meet both customer and regulatory specifications.

TPI: Please elaborate on the most recent innovation you have integrated into your manufacturing processes. What new products are you planning to launch within this category?

NV: Some of the recent innovations include advancements in stainless steel grades, crimping technology for fittings, anti-corrosion coatings and surface treatments, innovations in pipe bending and fabrication and lastly lightweight stainless steel pipes innovation.

We have introduced newer grades of stainless steel, such as 304L and 316L, which are being used more frequently in plumbing systems for their corrosion resistance and long-lasting durability. These materials are particularly valuable in environments with high levels of moisture or chemicals (e.g., coastal areas or industrial settings).

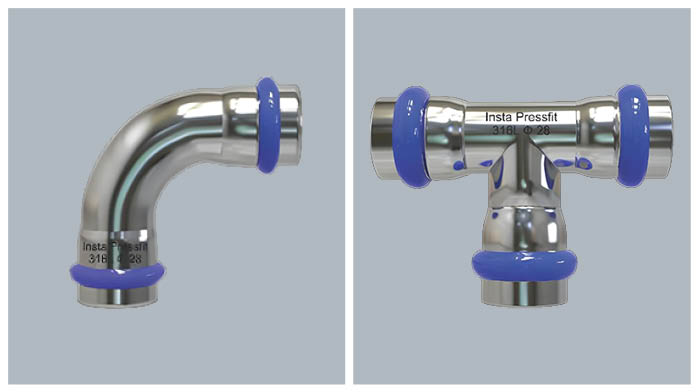

Further, crimping technology for stainless steel pipes and fittings have become more common. These systems offer quick installation without the need for welding, making them ideal for residential and commercial plumbing applications. These fittings are designed to be both strong and leak-proof, reducing installation time and potential failure points.

Moreover, new surface treatments are being developed to further improve the corrosion resistance of stainless steel pipes, especially for plumbing in highly corrosive environments like coastal areas or in industrial applications.

Further, we have made significant advancement in pipe bending technology, with machines now capable of bending stainless steel pipes to tighter radii and more complex shapes without compromising the pipe’s structural integrity. This allows for more customized plumbing installations, reducing the need for additional fittings.

And lastly, while stainless steel pipes are generally known for their strength, recent innovations have led to the development of lighter-weight stainless steel pipes that retain the same strength and durability while making them easier to handle and install.

TPI: In which industries do your SS tubes and pipes find application? Are there any new sectors you are considering for expansion?

NV: Stainless steel (SS) tubes and pipes have a wide range of applications across various industries including construction, oil and gas, food processing, pharmaceuticals, automotive, and aerospace, due to their excellent combination of corrosion resistance, strength, durability, and versatility.

With new innovations in material properties, as well as the continued growth of sectors like renewable energy, biotechnology, and water treatment, there is significant potential for expansion into emerging markets.

In the construction and plumbing segment, SS tubes and pipes find application in water supply and drainage systems, especially in high-humidity environments or areas prone to corrosion. It is also used in the fire protection system where stainless steel is preferred for fire sprinkler systems due to its high temperature resistance and strength.

SS tubes and pipes has also found application in the oil and gas sector where it is used in offshore and onshore drilling rigs. The pipes are used to withstand extreme pressures and harsh chemical exposure. It is also used for transporting fluids (e.g., crude oil, natural gas) through pipelines. SS tubes and pipes are used in refineries and petrochemical plants as they have high resistance to corrosion, especially in environments with hydrogen sulphide, chlorides, and other corrosive materials.

Further, SS tubes and pipes are used in the food and beverage industry for processing and transportation of liquids (water, milk, juices, etc.), ensuring hygiene and resistance to corrosion. Stainless steel is also used in the brewery systems, wine production, and dairy production, where it is the preferred material for tanks, pipes, and tubing. SS steel is used in food processing equipment, as it is easy to clean and doesn’t contaminate the product.

In chemical and pharmaceutical industries, SS tubes and pipes are utilized in the piping systems for chemical transport and reaction chambers. The process piping is also used for liquid and gas transfer in production plants. It also finds function in pharmaceutical manufacturing, including high-purity applications, where sanitary standards are paramount.

Moreover, stainless steel is used in aerospace and aviation because it is a lightweight yet strong compound, enough to handle the pressures in aviation systems. It is resistant to fatigue, corrosion, and wear in demanding environments. Moreover, stainless steel’s thermal resistance makes it suitable for high-heat environments like aircraft engines. Some of the applications include aircraft fuel lines, hydraulic systems, and ventilation systems. It is also used in parts like tubing for oxygen systems and fuel injection lines.

Finally, in the automotive industry, stainless steel is widely used for exhaust systems such as exhaust pipes and mufflers due to its high resistance to heat, corrosion, and the harsh conditions in engine compartments. It is also used in fuel lines, brake lines and coolant piping. Moreover, structural components in vehicles, such as roll bars, frame reinforcement, and body panels also use stainless steel.

Some of the emerging sectors and opportunities for expansion of SS tubes and pipes include renewable energy and water treatment and desalination. Stainless steel tubes are being used in solar panel frames and in the plumbing systems for concentrated solar power (CSP) plants. It is also increasingly used in the production of structural components and piping for wind turbines.

As the renewable energy sector grows, stainless steel’s role in supporting the infrastructure for both solar and wind power plants is expected to increase.

Apart from that, stainless steel is also used in pipes and tubes for transporting water, as well as in the reverse osmosis process. It facilitates water treatment systems for municipal, industrial, and wastewater management.

TPI: What strategies do you employ to maintain brand visibility?

NV: Maintaining and enhancing brand visibility is a multi-faceted effort, especially in industries like stainless steel pipes and fittings where competition can be fierce and the market can be highly specialized.

Some of the key strategies used by us to boost and maintain brand visibility are digital marketing and online presence, attending and exhibiting at major industry-specific trade shows, networking and strategic partnerships, product innovation and brand positioning, customer-centric engagement, and email marketing and automated campaigns.

Having a user-friendly, SEO-optimized website is a core part of our digital marketing and online presence, ensuring that our potential customers can easily find our products and services. Regularly publishing industry-relevant content, such as blog posts, case studies can position our brand as a thought leader. Moreover, leveraging platforms like Facebook, LinkedIn and Instagram for both B2B and B2C engagement is running on. Posting regular updates, product features, behind-the-scenes looks at manufacturing, or industry awards and certifications helps build both trust and awareness. Platforms like YouTube are also under planning to be used as an effective medium for showcasing product demonstrations, installation processes, and customer success stories. Paid Advertising (PPC) such as running Google Ads or social media campaigns can increase visibility among users actively searching for stainless steel piping solutions.

Furthermore, email marketing and automated campaigns keep the brand top of mind. Collaborating with industry influencers, and creating an affiliate marketing program where distributors, consultants, or even end-users get a commission for recommending your products can be a great way to expand your reach.

Regularly releasing new products or improvements to existing ones is essential for brand visibility and brand positioning. The growing demand for eco-friendly products globally, and products made using recycled materials can position our stainless steel pipes as sustainable, attracting environment-conscious customers.

Moreover, providing exceptional after-sales support, offering easy warranty claims, loyalty programs and incentives, technical support, and rapid delivery systems builds customer loyalty and encourages repeat business.

In the competitive market for stainless steel pipes and tubes, maintaining brand visibility requires a multichannel approach. By leveraging digital marketing, engaging with industry-specific events, fostering strong customer relationships, focusing on innovation, and building a reputation for quality and sustainability, brands can not only maintain but also grow our visibility across target markets. Whether the goal is to increase market share in plumbing, oil and gas, automotive, or renewable energy, a cohesive strategy is essential to building long-term brand recognition and trust.

TPI: Sustainability is increasingly important for businesses today. How significant is it in shaping your company’s identity, and what measures do you take to uphold it?

NV: For Insta Pressfit®, sustainability isn’t just a moral imperative—it directly influences the brand’s identity, competitive positioning, and customer loyalty.

Sustainability plays such a critical role in terms of customer expectations, long-term financial performance, regulatory compliance, and employee and community engagement.

Sustainable practices in manufacturing, such as resource optimization, waste reduction, and energy efficiency, can reduce costs in the long run. Investors and stakeholders are increasingly focusing on businesses that align with Environmental, Social, and Governance (ESG) criteria. Sustainability has become a valuable asset in attracting investment, securing government grants, and gaining access to green financing.

Moreover, governments and regulators are introducing stricter environmental standards such as carbon emissions targets, waste disposal regulations, and sustainable sourcing rules. Businesses that integrate sustainability into their operations are better prepared for compliance, and this helps avoid penalties and ensures smoother market access.

Local communities are more likely to support businesses that invest in sustainable development and practice corporate social responsibility (CSR), building goodwill and improving brand reputation.

To ensure that sustainability remains a key focus and is actively upheld, Insta Pressfit® has implemented a range of strategic measures. We adhere to energy efficiency in the production process and ensure waste reduction and recycling. We also incorporate recycled steel and provide supply chain transparency. Additionally, we design and innovate durable and long-lasting products and ensure sustainable coatings and materials. Reducing the use of plastic packaging or switching to recyclable materials for product packaging can further reduce the environmental impact of the product lifecycle. To further reduce the carbon footprint in shipping, we often look for ways to optimize logistics, such as using more fuel-efficient vehicles, reducing transportation distances, or consolidating shipments to minimize emissions. Moreover, we are obtaining environmental certifications and eco-labelling. We also provide sustainability training to our employees and incentivize sustainable practices.

Also Read: Renny Strips: Redefining Steel Excellence with Sustainable Manufacturing

TPI: Could you outline the challenges you have faced recently that have affected your operations?

NV: The challenges faced are multifaceted, ranging from supply chain disruptions to technological transformations and regulatory changes.

These challenges created significant operational hurdles, affecting everything from cost management to timely product delivery. However, through adaptation, investment in technology, strategic partnerships, and a commitment to sustainability, Insta Pressfit® not only overcame these obstacles but also positioned itself for long-term success in an increasingly competitive and environmentally-conscious marketplace.

TPI: What is your company’s vision over the next five years? What additional steps would you need to take to realize this vision?

NV: Our vision for the next five years is to become a global leader in the production of high-quality, sustainable stainless steel pipes and fittings, leveraging cutting-edge technology, a circular economy approach, and customer-centric solutions. We aim to contribute to building a more sustainable and connected world by providing durable, eco-friendly piping solutions across diverse industries.

Some of the key aspects of this vision include global expansion, sustainability leadership, technological innovation, customer-centric growth, and operational excellence.

To achieve this ambitious vision, Insta Pressfit® is dedicated to focus on several key strategic initiatives and operational steps such as investing in sustainable manufacturing, expanding market reach and global presence, diversifying geographic markets, and leveraging e-commerce and digital marketing.

The company further drives technological innovation through smart manufacturing and industry and product innovation like smart pipes and sensors. To strengthen customer relationships and service offerings, they plan to provide customer support and technical services, and customization and niche markets.

To strengthen internal capabilities and operational efficiency, the company plans talent development and recruitment, lean manufacturing and supply chain optimization, digitalization of operations, and achieve regulatory compliance and certifications.

By leveraging these initiatives, Insta Pressfit® plans to strengthen its position as a leader in the global stainless-steel pipes and fittings market.