Japan based San-Eki, the sole combined supplier of weld and pilger mills, has joined hands with OM Techcorp, India, to become the single source provider of Japanese tube rolling mills, exotic material and process know-how for rolling of high nickel, titanium, double melt material seamless tubes in special sizes. This was revealed by Mr. Takeshi Shimada, President, San-Eki Limited, during his recent interaction with Tube & Pipe India.

Leading manufacturer of 2 and 3 roll pilger (tube cold rolling) mills and tube weld mills, San-Eki, has synergised with OM Techcorp, India to become the single source provider of Japanese tube rolling mills, exotic material and process know-how for rolling of high nickel, titanium, double melt material seamless tubes in special sizes.

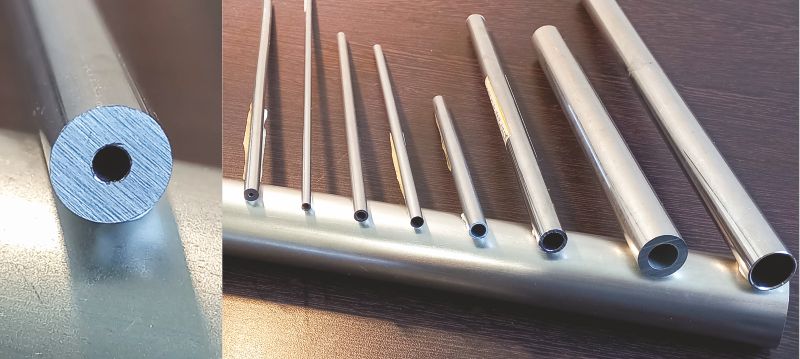

Established in 1957 in Japan, San-Eki is the only company to supply both weld and pilger mills and technology. These mills are used by clients to produce seamless & welded tubes for critical applications like aerospace, nuclear, medical, semiconductor, automotive, process equipment involving high grade material (nickel alloy, SS, titanium alloy) and precision tolerances.

The products of San-Eki find application in various industries such as power generation, shipbuilding, chemical, petrochemical & refinery, oil & gas, fertilizer, nuclear, aerospace & defence, space, medical & life sciences, automotive, food and beverages, and semiconductor.

They are also used in heat exchanger, condensers, instrumentation, super heaters, surgical tools, inter stage coolers, precision tubing (liquid chromatography), fuel lines, structural and actuation tubes, boiler tubes, control tubes, and high purity tubes.

For the Indian market, San-Eki is collaborating with OM Techcorp to provide mills for specialized tubing product and process development, consultation for critical material manufacturing (Ti Alloys, Zr, Ta, Nb, Ni etc), and high quality & critical grade raw material supply for tube manufacturing.

The demand for speciality and high precision tubes is not only growing in India, but there is also an excellent export opportunity from India in sectors of hydrogen, semiconductor and aerospace.

We intend to encourage and support Indian tube manufacturers to indigenously produce speciality tubes for domestic as well as exports. Our commitment to the Indian market is strengthened with our regular participation in trade fairs related to tube & pipe, hydrogen technology, and semiconductor. We create awareness on speciality tube production technology for critical sectors.

Also Read: ISEND: Spearheading Digital Transformation through Industry 4.0 Integration

Tubing for hydrogen application produced on San-Eki mills have high quality ID surface, heavy wall and made of high purity austenitic stainless-steel material, thereby providing good hydrogen embrittlement resistance and realising stable hydrogen flow. Tubes produced on the mill have high surface inner & outer quality (Ra 0.09 – 0.2), making it ideal for hydrogen and semiconductor application.

Presently, San-Eki is executing 2-roll and 3-roll pilger mills orders for Indian companies and we look forward to sharing our expertise with ever growing Indian tube producers and industrial consumers.