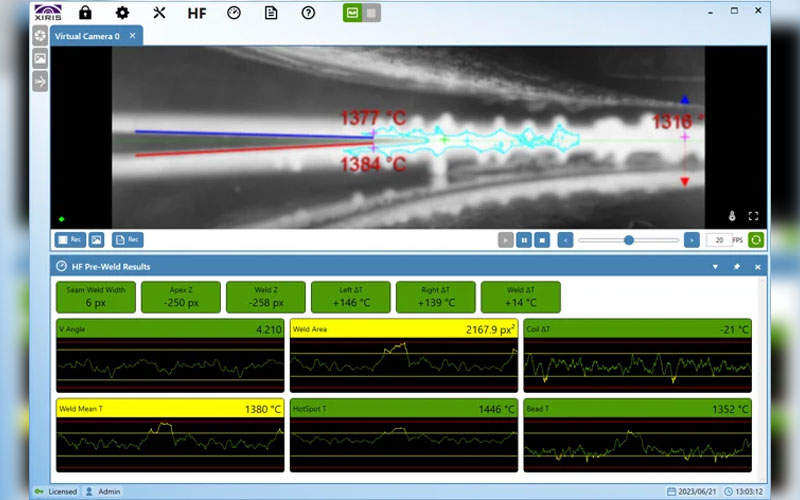

Xiris Automation has launched its Pre-Weld Inspection system for HF tube mills. The system measures and tracks the position and temperatures of various features of the tube as it heats up and is formed at the induction coil. The system is easy to set up and define tolerance limits, reporting results in real-time to the operator.

Jul 25, 2023

Xiris Automation recently released its Pre-Weld Inspection system for HF tube mills. With a goal of meeting the long-standing needs of tube fabricators to monitor tubes going into the weld box on a High Frequency (HF) tube mill, the system measures and tracks the position and temperatures of various features of the tube as it heats up and is formed at the induction coil. Using a thermal camera specifically designed to measure temperature in the range of hot metals (e.g. 350-1800°C), the Pre-Weld inspection system is easy to set up and define tolerance limits, reporting results in real-time to the operator.

Also Read: Welspun Corp Ltd: Building a Future-Ready Organization by Diversifying Portfolio

The system includes dimensional features such as V angle and V length, and actual temperatures of the strip edges, weld point and resulting bead, which can be more effectively monitored to detect whether the tube welding process remains within control. All thermal image video and extracted feature data can be recorded for further evaluation for quality assurance. It also comprises a robust housing for the camera that is capable of withstanding the harsh environment of the immediate area of the induction coil on most HF tube mills, using air to keep the optics area clean. The system comes with a ruggedized HMI controller with several interface options to integrate with the tube mill and plant process monitoring systems.