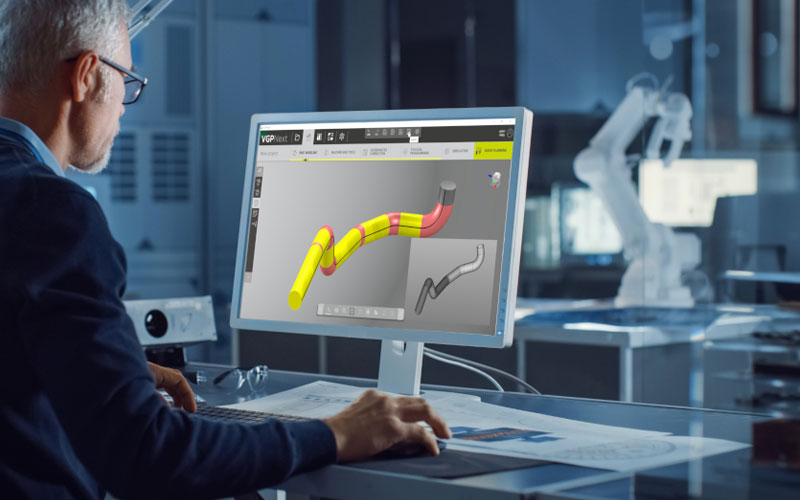

BLM Group has introduced a new CAD/CAM programming software called VGPNext for BLM Group tube bending and wire bending machines, that tackles the latest technological challenges. With VGPNext you can identify the part program right away, simulate the job and start production in just a few clicks.

May 11, 2023

BLM Group recently introduced VGPNext, the new CAD/CAM programming software for BLM Group tube bending and wire bending machines that tackles the latest technological challenges. The software features a completely revolutionized graphical user interface, with a multitude of features designed to make the machine programming more practical and simpler. VGPNext improves the synergy between machine and software by simplifying core functions for more user-friendly programming. With VGPNext you can identify the part program right away, simulate the job and start production in just a few clicks.

Also Read: MSS Steel Tubes USA to Setup Steel Tube Mill For Nextracker’s Solar Tracking Systems

The software provides multiple methods and features for programming parts. VGPNext allows you to choose a program from the library, containing all the programs on the server in one place, providing the convenience of preview images and numerous search filters to make this step even easier. The software’s B_import module saves a lot of time and allows less experienced operators to quickly become familiar with the program. The entire programming flow is more user-friendly with the help of a ribbon bar that assists the operator by indicating missing steps, incorrectly filled-in data, default data and user-modified data. In this way, VGPNext considers all possible variables – including theoretical coordinates, springback, material elongation, bending feasibility, choice of tools, etc. – and indicates how to intervene. The software also has additional features like 3D simulation and time estimation, targeted defect correction, monitoring and plug-ins.