Established in 1985, Hi-Tech Pipes Limited (HTPL) is a leading manufacturer and supplier of ERW pipes in the Indian piping industry. The company specializes in steel tubes and pipes for a variety of industries, such as infrastructure, telecommunications, defense, railroads, airports, real estate, and automobiles. The company, with a current total capacity of 5.8 lakh metric tons and a total workforce close to 1500+, has 6 state-of-the-art manufacturing facilities located at Sikandrabad (Uttar Pradesh), Sanand (Gujarat), Hindupur (Andhra Pradesh) and Khopoli (Maharashtra), as well as an upcoming facility in Makhiyav, Gujarat which will increase the production capacity close to 8 lakh tons. The company is currently planning multiple developments, with an aim to reach the manufacturing capacity of 1 million tons by FY26. In a recent interaction with Tube & Pipe India, Mr. Ajay Kumar Bansal, Chairman & Managing Director, Hi-Tech Pipes Limited, shared the company’s overview, manufacturing plants, sectors catered, the organization’s recent developments, current trends in the Indian tube and pipe industry, the company’s future plans, and many other topics.

Tube & Pipe India: Please share Hi-Tech Pipes’ journey, major milestones, and crucial achievements.

Ajay Kumar Bansal: Hi-Tech Pipes Limited (HTPL) is a NSE and BSE listed company established in the year 1985. During the period of 1988 to 2001, the company commenced manufacturing MS pipes at its Sikandrabad unit 1, where it manufactured cold rolled coils and strips too. From 2001 to 2012, HTPL installed a hot-dipped galvanizing facility, commenced the production of highway crash barriers and began the production of hollow sections and solar mounting sections. Following this, in the period of 2012 to 2016, the company commenced operations at Sanand in Gujarat for the manufacturing of ERW pipes, and modernized the Sikandrabad unit’s cold rolling plant. The company also got listed on the NSE-SME. Between 2017 to 2018, HTPL commenced operations at Hindupur in Andhra Pradesh for the manufacturing of ERW pipes, and commenced commercial operations for the manufacturing of steel tubes and hollow sections at its unit 2 at Sikandrabad, as well as the Sanand unit in Gujarat. In May 2018, HTPL became the third company to migrate to the NSE Main Board. The company received many accolades within 2018 to 2020, including the Secondary Steel Sector award from the Ministry of Steel, the Top Performer Award from SAIL, and the Ispat Rachna Award from the Ministry of Steel, Government of India. The company started its third tube mill at Sanand, installed solar plants at Sikandrabad, Sanand and Hindupur units, and started a cold rolling expansion project for wider HRoP, CRCA and CRFH production, within this period. From 2020 to 2023, HTPL commenced operations at Khopoli in Maharashtra, started a continuous galvanizing line at Sikandrabad, got listed on BSE, and started the manufacturing of colour coated coils and sheets.

TPI: What is the manufacturing set-up and production capacity of your plant?

AKB: The company is present across three critical regions in the country, with 6 state-of-the-art manufacturing facilities located at Sikandrabad (Uttar Pradesh), Sanand (Gujarat), Hindupur (Andhra Pradesh) and Khopoli (Maharashtra), currently having a total capacity of 5.8 lakh metric tons, providing complete range of products in steel tubes and pipes, structural steel, flat steel and highway safety segments. In addition to this, our new state-of-the-art facility of large dia pipes, located in Makhiyav, Gujarat, is in the advanced stage of commissioning. With this upcoming facility the total production capacity will reach close to 8 lakh metric tons.

TPI: Please tell us about your product portfolio and its applications.

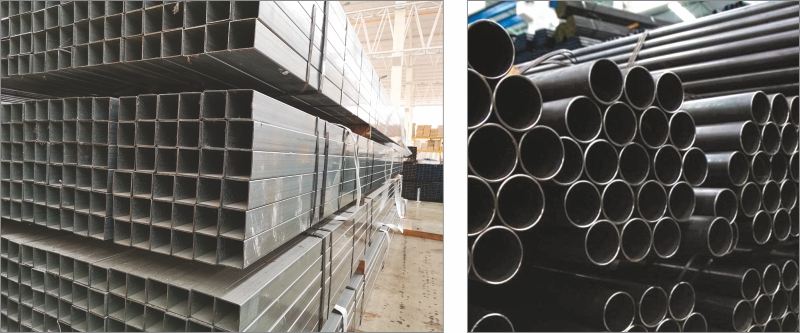

AKB: Having an experience of nearly four decades, Hi-Tech Pipes today is one of the leading steel processing companies and among the third largest Indian producer of world-class innovative steel products, with a rich product portfolio of over 1200 SKUs. The company has a strong presence in black steel tubes and pipes, galvanized steel tubes and pipes, pre-gal pipes, jumbo steel sections, solar torque tubes, cold rolled coils and strips, GP/GC coils and sheets, color coated coils, metal beam crash barriers. Our products have been supplied to the Jal Jeevan Mission scheme, as well as industries like infrastructure, real estate, agriculture, defense, telecom, automobile, OEM, EPC, roofing, white goods, wall cladding and others. With a constant drive to move up the value chain, the company’s emphasis is always on increasing the value added products and offering a wide variety and range of products across segments. Over a period of time, the company has developed many new applications for its products viz. green house, defense shelters, telecom towers, solar mounted structures, renewable energy, and others.

TPI: Please shed light on your market footprint and USP.

AKB: Hi-Tech Pipes has a pan-India market presence with a strong distribution network of 450+ dealers and distributors, 150+ OEM customers, 365+ architects, builders and contractors, 1200+ SKUs, and 6 manufacturing plants catering to northern, southern and western geographies. At HTPL, our operations revolve around the production of a diverse range of steel pipes and tubes, serving the needs of various industries, including infrastructure, telecommunications, defense, railroads, airports, real estate and automobiles, among others. The company has also successfully established its steel products presence in the global market and has become a globally trusted brand by exporting its product in European, Middle East and South East Asian countries. This broad market coverage works as a USP as it allows us to focus on creating products that receive positive feedback and remain competitively priced. To drive operational excellence, HTPL continuously undertakes initiatives to enhance process efficiencies and engage in dedicated research and development efforts. The company’s commitment to improvement is ongoing. In addition, our manufacturing processes benefit from a robust inbound and outbound logistics and distribution network. The company’s USPs also includes a comprehensive product portfolio with a complete range of steel products, a strong distribution network, great export potential, 6 state-of-the-art manufacturing facilities located at key strategic locations, best in quality products, strong supply chain, and prudent fiscal management.

TPI: Could you tell us about the recent or upcoming developments at your company?

AKB: Recently we have started our GP/GC line and a color coating line at our Sikanderabad facility, seamlessly integrating it with our existing cold rolling facility. This strategic upgrade not only optimizes our production capacity but also effectively meets the rising demand for GP/GC and color coated roofing sheets, all while guaranteeing superior durability and extended lifespan.

Additionally, we have commissioned another hot dipped GI plant at our Sikanderabad facility to cater the rising demand of GI pipes. We are also embarking on commissioning a new manufacturing facility at our Makhiyav, Sanand facility, which will be dedicated towards the manufacturing of large-dia pipes addressing the growing need from the Indian water, infrastructure and oil and gas segment.

TPI: Can you share with us your observations on key market trends in the Indian tubes and pipes market?

AKB: The Indian steel pipes industry is expected to experience substantial growth in the year ahead.

According to the industry experts, the Indian steel pipes industry is expected to grow at a CAGR of 7.5% during 2023-2027, driven by the increasing demand from the construction, oil and gas, agriculture, defense and automotive industries, among others. The Indian infrastructure industry is one of the largest consumers of steel pipes in India, accounting for over 50% of the total demand. The growth of the construction industry is being driven by the government’s infrastructure development initiatives, such as the Jal Jeevan Mission, Dedicated Freight Corridor, Pradhan Mantri Gram Sadak Yojana (PMGSY) and the Smart Cities Mission. The oil and gas industry is another major consumer of steel pipes in India. The demand from the oil and gas industry is expected to grow in the coming years, as India increases its exploration and production activities. We expect a surge in steel tubes and pipes demand driven by 5G telecom market as well. Additionally, we will be servicing renewable energy market as well, especially towards solar power. Further demand for steel pipes is being driven by the steady growth in some of the other key sectors such as agriculture, defense and renewable energy, among others. In addition to the domestic demand, the Indian steel pipes industry is also expected to benefit from the growing exports of steel pipes to countries in the Middle East, Africa, and Southeast Asia, among others. Moreover, the central government’s allocation for huge capex towards infrastructure, which includes railways, airports, telecom, green hydrogen, agriculture and water supply schemes for the next 4 to 5 years are surely big demand drivers for our steel products.

TPI: Hi-Tech Pipes’ FY 23 performance as of yet has been far more successful than the previous FY. Can you identify for us the indicators of better performance and drivers for the same?

AKB: Our FY23 was marked by another year of commendable performance across different product categories, with market share gains and improvement in operating margins, as compared to FY22. For FY23, we witnessed a revenue growth of 27%. During the year, we continued to focus on our customers through focused production innovation and brand building initiatives. Additionally, new customer additions across different product segments was another focus area for the company. In FY23, the company delivered a remarkable overall performance. This progress was aided by growth across the company’s strategic business units (SBUs). The revenue from operations, including other income, stood at INR 2,385 crore, which was 27% higher as compared to the previous year. Sales volume of the company has grown by 28% YoY, standing at 3.55 lakh MT. The company undertook several enhancements in the product mix, improved realizations, and cost-reduction efforts that helped deliver better margins. Profit before Tax and Exception Items (PBT) came in at INR 56.40 crore, up by 2% from last year. In line with the increase in revenue, resilient realization gains and healthy volume growth aided the financial performance. During the year, the company’s efforts to add innovative products to its portfolio complemented its growth trajectory. End-user demand remained strong, and HTPL capitalized on this opportunity by demonstrating agility throughout its operations. In line with our vision to become a net debt free entity by FY 2025, we have reduced the substantial amount of long term and short borrowings, there is a 35% reduction in the same. Reduction in borrowings was largely because of the regular repayment of long-term secured loans. Besides this, the share of value added products in the product portfolio of the company has grown from 20% to 27% in FY23.

TPI: What is your company’s business roadmap?

AKB: Hi-tech is well equipped with the latest state-of-the-art manufacturing facilities located in various strategic locations in the country, catering the Northern, Southern and Western markets. Since our inception, our primary goal has been to earn industry recognition and grow with a sense of pride. Thus, we have diligently focused on periodically improving various aspects of our business and effectively implemented our strategies, resulting in an impressive production capacity of 0.58 million MTPA. As we persist in our pursuit to ‘Rethinking our Tomorrow’ for a more promising future, our objective is to position Hi-Tech Pipes Limited not merely as a well-known brand or a piping solutions provider, but also as a company recognized for its ability and capacity to deliver. This objective holds great significance for us at Hi-Tech Pipes Limited, as it signifies our vision and pride, propelling the company to the next level. We believe that building this resilience is crucial as it will enable us to seize the emerging opportunities.

TPI: What are your vision and plans for your company’s future?

AKB: We aim to achieve our growth objective by reaching the manufacturing capacity of 1 million tons by FY26. With this expansion, we will be able to cater to large customers and fulfill substantial orders with a diverse range of products, positioning Hi-Tech Pipes Limited as a comprehensive solution provider while benefiting from economies of scale. Additionally, we aim to strongly dedicate our efforts towards the upcoming projects and adding the value added products in the company’s product basket. Our upcoming new facility at Makhiyav, Gujarat (Sanand Phase II) will be a game changer for the company. With the start of this greenfield facility, we will be able to demonstrate our performance to next level.