ISEND S.A. is a technological company that designs, manufactures, and implements pioneer solutions for process and quality control. It is based on the technology of Eddy Current and integrated with Artificial Intelligent, Artificial Vision and Big Data Analysis (using neuronal nets and algorithms) for decision making. All this has software tools that put the information in an easy and accessible way for the end users. In an Interview with Tube & Pipe India, Mr. Pablo Gutierrez Azanza, Client Representative, ISEND S.A. talks in detail about the solutions provided by the Company and the technological roadmap along with their key vision.

Tube & Pipe India: Could you please give us a brief outline of the core business of your company?

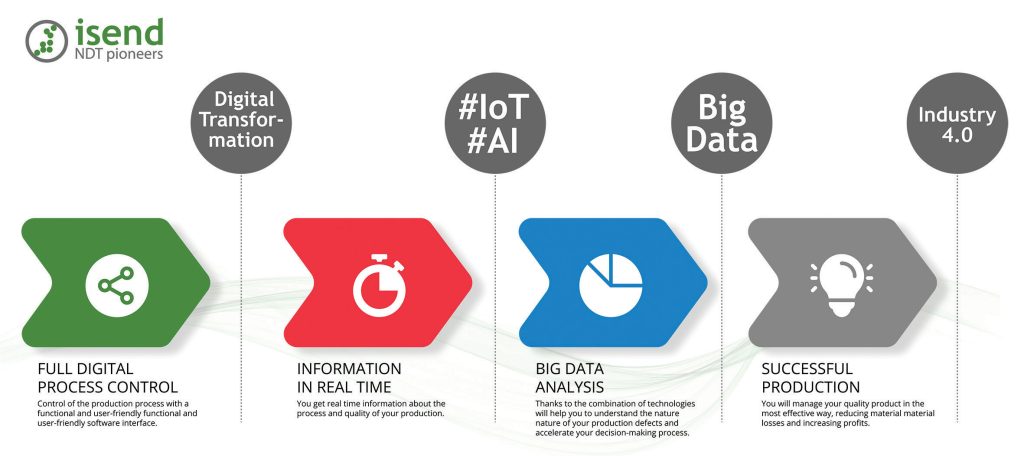

Pablo Gutierrez Azanza: ISEND is a technological company that designs, manufactures, and implements pioneer solutions for process and quality control. Our solutions help in the digital transformation of the company, making it a smart factory by implementing industry 4.0 solutions. We have solutions that integrate Eddy Current technology with Artificial Vision and Artificial Intelligence. All this generates a lot of data coming from the process. This data is managed with Big Data analysis that helps identify and solve deficiencies in the process and the product. The software package contains different tools and helps the customers to have all the information accessible in an easy way. We are based in Spain but we work with customers in different countries across the world such as all of Europe, the United States, India, Thailand, and South Africa.

TPI: Kindly cast some light on the solutions you provide and their advantages.

PGA: Our focus is on the process, product and quality control with Artificial Intelligence and Artificial Vision integrated with Eddy-Current technology that enables the digital transformation of the customer. ISEND solutions are focused on a wide range of industrial applications. Our set of solutions is created to fit the requirements of our customers.

We design, manufacture and deploy NDT (nondestructive testing) solutions based mainly on Eddy Current technique, Artificial Vision, Artificial Intelligence and Big Data analysis for online and offline metals inspection on metal producers. For example, in tubes, we can identify and prevent potential defects or leaks before their service life is reached, which helps to control the process and the quality.

TPI: Which industries do you serve with your solutions?

PGA: ISEND can offer different solutions for all kinds of customers. In the specific sector of tubes, we have solutions for seamless tubes, welded tubes, and solutions for 360º inspection of the tube or for welding inspection, in ferromagnetic and non-ferromagnetic materials. All the data is processed in a digital way and our R&D department works in close collaboration with our customers in order to continuously improve ISEND’s solutions.

We offer solutions for each need, our EDDYEyes for process and quality control in hot rolled producers detects the defects and classify them with Artificial Intelligence (neuronal nets and algorithms), HOTdiscover detects many types of defects in hot rolled rod products by Eddy Current technology, ROTOdiscover detects longitudinal defects in cold formed long products by using rotating probes, WELdiscover detects defects in the welding area of the tubes, ENdiscover detects punctual and transversal cracks in cold formed long products, DEFdiscover detects defects in components, it’s usually combined with robotic solutions. MATdiscover classifies metals by physical properties such as composition, hardness or conductivity.

Our solutions are unique in the market and are part of the IoT technology since the user does not need to go to the production line and check what is happening, instead all the information will be displayed directly on the computer.

“Integrating smart and digital new technologies and bringing novel innovations are the ‘strategic point of view’”

TPI: Share your outlook on the tube & pipe industry. How do you see the market evolving in the future?

PGA: We are facing a very peculiar situation coming from the effect of the Chinese manufacturers, the Russia-Ukraine war the United States high demand and the increase in the price of raw materials. The market is affected by several factors right now which were not forecasted by the market trends. However, even with this situation, we see that all the tube & pipe manufacturers are doing well and able to sell their products. So although the general environmental conditions are unpredictable, the steel market generally looks good; and we hope that in the near future, it would be better.

Also Read: Mechatronics to Set Up a Manufacturing Unit in India

TPI: What is your technology and business roadmap for the future?

PGA: Integrating smart and digital new technologies and bringing novel innovations are the ‘strategic point of view’ of our company. We want to help companies in a digital world to improve their process, reduce CO2 emissions, and join our efforts with the customers to make a better environment.