The tube and pipe manufacturing industry is characterized by its relentless pursuit of precision, efficiency, and reliability. In this dynamic and competitive sector, where product integrity is crucial, Xiris Automation Inc. has emerged as a leader with its advanced weld inspection solutions, namely the WI2200 and WI3000 systems.

Xiris WI2200: Precision for Small to Medium Tubes

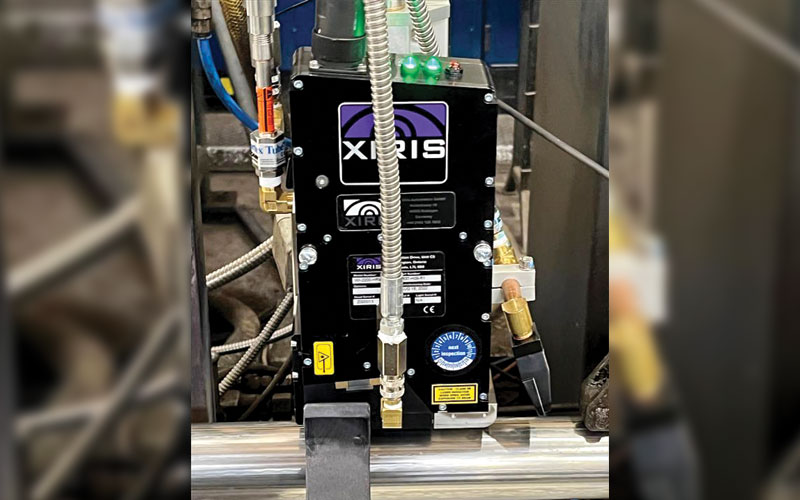

The WI2200 stands out as a laser-based 3D post-weld inspection system tailored for tube and pipe mills handling outside diameters ranging from 5 to 200 mm. This system offers real-time feedback on weld quality, empowering operators to make instant adjustments during production. With non-contact, non-destructive sensors, the WI2200 ensures uninterrupted processes, essential for maintaining production efficiency.

Key Benefits of WI2200

Simplified Mill Setup: With real-time feedback, mill setup time is significantly reduced. Operators can quickly fine-tune the equipment, leading to faster production start-ups and reduced downtime.

Enhanced Forming and Weld Quality: Continuous in-line monitoring ensures that tubes meet stringent quality standards, reducing the likelihood of defects.

Cost Reduction: By minimizing material scrap, customer returns, and product liability claims, the WI2200 helps lower operating costs.

Improved Efficiency: The system’s ability to provide real-time process monitoring, trend reporting, warnings, and alarms translates to better overall mill efficiency.

Xiris WI3000: Robust Solution for Large Diameter Tubes

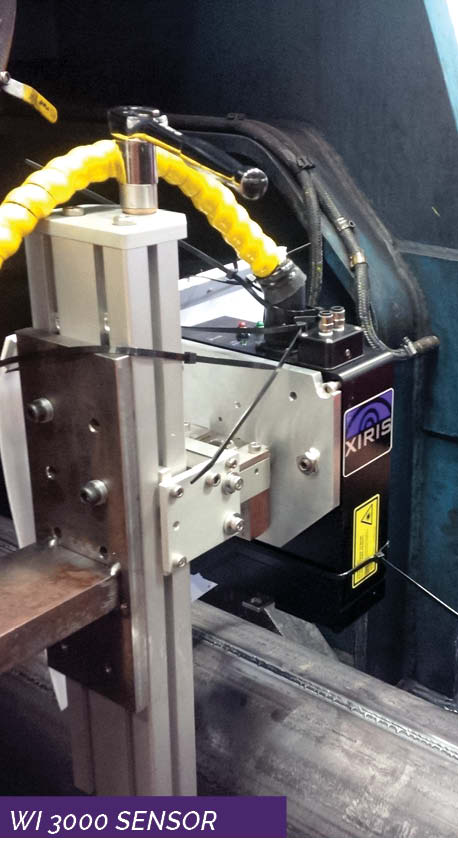

For larger high-frequency tube and pipe mills, WI3000 offers a robust solution. Designed for tubes with outside diameters exceeding 13 mm and capable of inspecting diameters above 600 mm, WI3000 features a rugged package with water-cooled sensors. It shares many benefits of WI2200, including real-time feedback and enhanced weld quality, with added durability for harsh manufacturing conditions.

Adoption of Xiris’ WI Series by TATA Steel

The impact of Xiris’ WI series on the tube and pipe industry is underscored by its widespread adoption by industry leaders like TATA Steel. Notably, TATA Steel installed the first WI2200 system in India at its Jamshedpur facility in 2023, marking a significant milestone in the Indian market. The subsequent installation at its Khopoli plant further demonstrates TATA Steel’s commitment to quality and efficiency. In the Netherlands, TATA Steel’s experience with Xiris’ solutions exemplifies their substantial return on investment, with over 10 systems installed across their mills.

Driving Efficiency and Quality in Tube Mills

The success stories from industry giants like TATA Steel highlight the transformative impact of Xiris’ WI2200 and WI3000 systems. These systems provide real-time, non-destructive inspection capabilities, ensuring unparalleled precision and quality.

The integration of non-contact sensors into existing manufacturing lines facilitates seamless operation without disrupting production. Continuous monitoring and instant feedback enable immediate corrective actions, reducing defects and enhancing customer satisfaction and manufacturer reputation.

Xiris’ WI2200 and WI3000 Systems Improving Weld Quality and Efficiency

Xiris Automation Inc.’s WI2200 and WI3000 weld inspection systems have set a new standard in the tube and pipe manufacturing industry. Their adoption by leading companies like TATA Steel underscores their effectiveness in improving weld quality, reducing costs, and enhancing overall mill efficiency. As more manufacturers embrace these advanced systems, Xiris remains at the forefront of driving innovation and excellence in the industry. For manufacturers striving to maintain competitiveness and uphold the highest quality standards, the Xiris WI2200 and WI3000 offer a proven solution delivering tangible results across diverse production environments, from small to large diameter tubes.

Xiris Automation Inc Terms Trade Fairs as Key Components for Global Brand & Marketing Strategy

Xiris Automation is a regular exhibitor at trade shows that cater to the welding, tube and pipe and additive manufacturing industries. These shows are key components of our global brand and marketing strategies. Our recent exhibits at Indian trade shows – especially those in the tube and pipe industry – have led to key account penetrations and increased brand awareness. Indian companies are looking for suppliers that are committed to supporting their business goals, and trade show presence – where face-to-face discussions can quickly lead to trust-building – are one of the only ways to show this commitment.

Also Read: KEC Bearings: Go-to-Brand for Efficient Bearings

Participation in Tube & Pipe Fair 2024: Xiris Expects High Quality Traffic

Xiris Automation is a regular exhibitor at industry trade shows – a key component of our global brand and marketing strategies. Indian companies are looking for committed suppliers to support their business goals, and trade show presence – where face-to-face discussions can quickly lead to trust-building – are one of the only ways to demonstrate this commitment.

We are expecting high quality traffic from decision-makers and technical experts from the major welded tube brands at the upcoming show. As always, we will promote our presence at the show via our social media and outreach channels.

Because we will have equipment and displays showing our solutions at the booth, we often are able to engage with prospects – discussing the advantages that our solutions offer. We also expect to have visits from some of our satisfied Indian clients – always an enjoyable experience.

Visit Stand: Hall 1 / F4 at Tube & Pipe Fair – Hyderabad