The CSP® Nexus plant is the third of its kind worldwide, which maximizes productivity, achieves peak values in terms of performance, efficiency, carbon reduction

Mar 15, 2024

Leading steel manufacturer JSW STEEL (Dolvi Works) has placed an order with SMS group to supply its trailblazing CSP® Nexus plant, which will fundamentally transform flat steel production. The plant, the third of its kind worldwide, not only promises maximum productivity, but also expands the product mix in terms of widths and thicknesses. It achieves peak values with regard to performance, efficiency and carbon reduction.

This is the second order from JSW Steel for a CSP® plant from SMS group. JSW has been operating a typical CSP® plant from SMS group very successfully since 1998. With its CSP® Nexus plant, SMS group, as a pioneer of thin strip technology, is setting new standards in the steel industry and will revolutionize the market on an ongoing basis.

The plant will be constructed at Dolvi site on the west coast of Maharashtra and put into operation in 2026. The CSP® Nexus technology in this new plant for JSW STEEL (Dolvi Works) is setting new standards in terms of productivity and dimensions of the final hot rolled products.

As the inventor of integrated casting and rolling technology, SMS has advanced this plant technology with every order. With each new order, SMS develops tailor-made solutions for specific market and customer requirements.

For the first time, hot strip and plate for shipbuilding, wind towers, heavy pipeline grades (API) or alike with a maximum width of 2,600 millimeters can be produced on a single plant that comprises casting and direct rolling. The hot strip thickness range of 2.0 to 32.0 millimeters is exceptional and offers JSW STEEL (Dolvi Works) a unique opportunity to open up new markets at a competitive cost level, particularly in the field of “green plate” production.

With parameters like these, the CSP® Nexus plant for JSW STEEL (Dolvi Works) is not only setting standards for thin slab casting and rolling plants, but also for conventional hot strip mills.

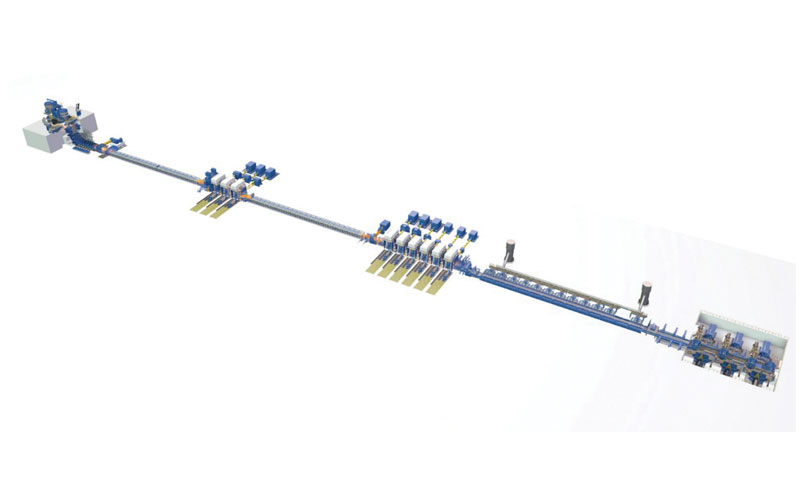

The scope of supply includes a single-strand caster with high throughput, a multi-stand roughing mill that can reduce the slab thickness to the optimal transfer bar thickness, and a six-stand finishing mill.

A highly advanced laminar cooling system and three down coilers are completing the plant. The scope of supply also comprises all the automation technology for controlling the plant, including drive engineering and the array of technology packages, which feature sophisticated process models from the X-Pact® family of automation solutions.

Also Read: SAIL to Set Up Greenfield Steel Plant in West Bengal with Around INR 24,000 Crore Investment

With an annual capacity of four million tons, this is the highest capacity for a single-strand caster of this type anywhere in the world. Provision is made for a plant extension, either a second casting strand or a lateral slab feeding facility, to further boost the productivity to more than seven million tons in future.

The bow-type casting machine is capable of casting slabs up to 160 millimeters. This ensures an appropriate reduction ratio for particularly thick products and allows for a production throughput of up to 8.5 tons per minute and, going forward, has the potential to deliver ten tons per minute.

Three roughing stands, located downstream of the first tunnel furnace, ensure the full range of transfer bar thicknesses. Even with larger slab dimensions, thin strip can be rolled. Roughing and finishing mill are decoupled by a heated roller table thus the roughing stands operate at highest rolling speed rates to meet the relevant temperature requirements and increase the overall energy efficiency of the plant.

In addition to the three roughing stands, a high-performance six-stand finishing mill ensures the desired hot strip thickness range. The laminar cooling section comprises nine super-reinforced microzone groups, which are designed to ensure both plant productivity and the mix of product dimensions. Three extremely robust down coilers complete the CSP® Nexus line.

Furthermore, SMS group equips the facility with a toolset of digital solutions that provide for the efficient use of plant data. By integrating the SMS DataFactory, the QES quality management system, and the GeniusCM condition monitoring software into the production processes, JSW will benefit from remarkable improvements in both efficiency and predictability. These innovative tools enable real-time data analysis, and data-driven decision-making, ultimately improving overall production quality and performance.

“With the CSP® Nexus plant at JSW, SMS, inventor of thin slab technology, is once again demonstrating its innovative strength in the field of casting and rolling technology. In contrast to other available thin slab casting and rolling concepts on the market, CSP® Nexus is not just putting focus on a rather limited range of final products. CSP® Nexus offers a tailor-made solution best fitting for the individual customer needs, which in case of JSW STEEL (Dolvi Works) are highest productivity with reduced energy consumption and CO2 footprint in combination with a boundary breaking range of final product dimensions.” says Cosimo Cecere, Head of Integrated Process Solutions Casting and Rolling Plants.