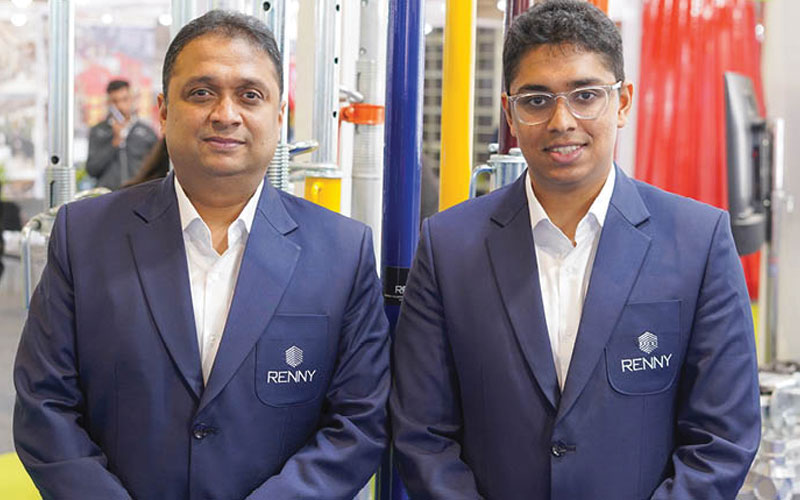

Going by a combination of technological excellence, sustainability and superior quality, Renny Strips Private Limited (RSPL) continues to set new benchmarks in the steel and pipe manufacturing sector. Having production capacity of 300,000 MTPA, RSPL produces 90 percent of its raw materials in-house and operates a 22 MW solar energy plant, leading to reduction of energy consumption by 75 percent and greenhouse gas emissions by 86 percent. Mr. Sarthak Gupta, CEO, Renny Strips Private Limited, revealed in an exclusive interaction with Tube & Pipe India that the company aimed to reduce its carbon emissions by 75 percent, making it compliant with CBAM regulations.

Tube & Pipe India: Please provide a brief introduction to the business journey of Renny Strips Private Limited, highlighting major achievements and crucial milestones.

Sarthak Gupta: Since its inception in 1996, Renny Strips Private Limited has been a driving force in India’s construction industry, particularly in the building material section. Founded by visionary leaders Mr. Dev Gupta and Mr. Binny Gupta in Ludhiana, Renny started with a mission to revolutionize the market with innovative, sustainable and competitively priced solutions.

Over the years, Renny has expanded into four major divisions – coils, pipes, scaffolding & formwork, and industrial paints – establishing itself as a market leader. Renny boasts of three state-of-the-art manufacturing facilities in Punjab with a production capacity of 3,00,000 MTPA, offering over 1,000 SKUs. The company’s product range includes premium quality HR coils, MS black, and galvanized round & hollow sections. Our products meet international standards such as BIS, EN, ASTM, and AS. Renny is certified with ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and EN 1090-2:2018.

The company has continued to innovate and grow under the next generation of leadership, represented by Mr. Sarthak Gupta. He spearheaded the launch of the scaffolding & formwork division and integrated modern technologies like AI-driven quality checks & IoT-based monitoring systems. Renny’s commitment to sustainability is evident in its advanced manufacturing practices and substantial reduction of carbon emissions through its solar energy plant. Renny’s diversified product offerings, including its fast-growing industrial paint division, continue to enhance its competitive edge. The company remains dedicated to expanding its product range, adopting sustainable manufacturing practices, and increasing its production capacity to maintain its position at the forefront of the industry. With an eye on both domestic and international markets, Renny is committed to delivering unmatched value and shaping the future of construction in India and beyond.

TPI: Kindly walk us through the company’s manufacturing facilities, infrastructure and machinery setup along with production capacity, with regard to Renny’s Pipes & Tubes Division.

SG: Renny’s Pipes & Tubes Division in Ludhiana, Punjab, is a state-of-the-art facility certified by TUV Rheinland for structural steel components under EN1090 standards. Utilizing advanced manufacturing processes, Renny ensures precision, uniform dimensions and standardized fittings, complemented by a hot-dip galvanizing process with a minimum zinc coating of 385 GSM for superior durability. Renny maintains a strategic inventory to ensure swift dispatches and meet immediate industry demands, reaffirming its commitment to delivering top-quality, reliable products for various industrial applications.

TPI: What are the key products offered by Renny in the pipes and tubes segment? How do you ensure quality and consistency across your product lines?

SG: Renny offers a versatile range of ERW pipes and tubes, including round, square (SHS), and rectangular (RHS) sections, available in finishes such as black, galvanized (GI), and color coated. Our portfolio features four distinct brands: Renny Bold (black round pipes), Renny Hero (hollow section pipes), Renny Guard (hot-dip galvanized pipes with 385 GSM zinc coating), and RSP (scaffolding pipes), catering to a wide range of applications in construction, water supply, firefighting and industrial engineering. With sizes ranging from 33-127 mm OD, thicknesses of 1.4-5.5 mm and compliance with global standards like IS:1239, BS1139, and EN 10219, Renny ensures superior performance and reliability.

TPI: How do you ensure quality and consistency across your product lines?

SG: The company’s robust quality assurance program includes hydro, drift, spectro, eddy current, bend & flattening tests, as well as detailed weld inspections, digital hardness testing, and automated strength & weight checks. Comprehensive post-weld treatments, precise measurements and CMM-based assessments for thread pass, coating and squareness further enhance product reliability & performance. Backed by a stringent quality management system (QMS) involving advanced raw material testing, multi-stage inspections and certified test reports, we combine cutting-edge technology and precision manufacturing to deliver products that consistently meet the highest industry standards.

TPI: Sustainability is a growing concern in the industry. How has Renny integrated eco-friendly practices into its operations?

SG: Renny has integrated several eco-friendly practices into its operations to address sustainability concerns. The company operates a 22 MW solar energy plant, which significantly reduces its energy consumption by 75 percent and cuts greenhouse gas emissions by 86 percent. Renny also focuses on using 100 percent recyclable steel and advanced manufacturing processes to minimize environmental impact. Additionally, the company has implemented rigorous water conservation measures and promotes a Circular Economy through effective waste management. These initiatives reflect Renny’s commitment to sustainability and reducing its carbon footprint while maintaining high-quality standards in its products.

Also Read: VR Coatings Eyes New Markets in Southeast Asia, North America, South America

TPI: What are the biggest challenges you see in the steel and pipe manufacturing sector today? How does Renny address these challenges?

SG: The steel and pipe manufacturing sector faces several significant challenges today, including raw material price volatility, low adoption of modern technology, a fragmented market, stringent regulatory standards, and environmental compliance. To combat raw material price volatility, Renny has integrated plant facilities that produce 90 percent of its raw materials in-house. This reduces dependency on external suppliers and minimizes cost fluctuations. Renny leverages state-of-the-art technologies such as CNC machines, robotic welding, IoT-enabled monitoring, and AR/VR training to ensure precision, efficiency, and innovation in manufacturing.

By focusing on high standards of quality and obtaining certifications like EN 1090, Renny ensures superior products that help the company to stand out in a competitive market. Rigorous testing protocols further reinforce its commitment to quality. The company is deeply committed to sustainability, operating a 22 MW solar energy plant that achieves a 75 percent reduction in energy consumption and cuts greenhouse gas emissions by 86 percent. It also implements advanced water conservation measures and promotes a Circular Economy through effective waste management. Renny’s carbon emissions are already 50 percent lower than the industry average and the company is aiming to achieve a 75 percent reduction. This ambitious goal not only strengthens compliance with CBAM regulations, but also offers significant benefits to customers by aligning with their sustainability objectives.

By combining technological excellence, sustainability and superior quality, Renny addresses these challenges and continues to set new benchmarks in the steel and pipe manufacturing sector. This approach ensures they remain competitive and capable of meeting the evolving demands of industries like construction, automotive and energy.