India’s water infrastructure is undergoing a quiet but important upgrade, and it is not steel, iron or concrete leading the charge. With its unmatched balance of strength, efficiency and longevity, PVC-O is steadily rewriting the rules of pressure piping across sectors.

India’s massive infrastructure drive, nudged by the Jal Jeevan Mission’s goal to connect 14 crore rural homes with piped water, alongside extensive urban housing and Smart City programs, has pushed traditional PVC-U and CPVC pipes to their limits. Widely used for their affordability and ease of installation, these materials now face constraints in high-pressure and long-distance applications, including cracking, biofilm buildup, elevated pumping costs, and limited mechanical resilience. In response, a new generation of pipelines PVC-O, or molecularly oriented PVC, is emerging as a transformative solution that combines polymer engineering with infrastructure-grade durability to meet India’s demanding requirements.

Why PVC Needs an Upgrade

PVC-O offers a leap beyond CPVC and conventional PVC in every key dimension. Unlike CPVC, which uses chemical modification to endure higher temperatures, PVC-O enhances strength via physical alignment of molecules. Rather than relying on additives that can degrade over time or complicate recycling, PVC-O preserves PVC’s chemical structure but arranges it in a layered, oriented state, unlocking mechanical properties on par with, or even better than, ductile iron—while remaining leakproof and entirely non-metallic. This makes it uniquely suitable for our modern water needs: energy-efficient, resilient under pressure, scalable for national projects, and sustainable over a century of service.

Technology Deep Dive | The Science of Molecular Orientation

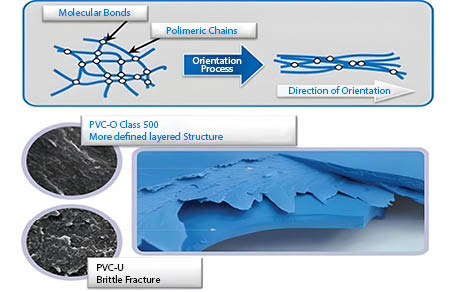

PVC-O starts with conventional unplasticized PVC (PVC-U), which is melted and extruded, then immediately subjected to biaxial stretching (lengthwise and circumferentially) under controlled heat. This realigns the polymer chains tightly in a specific orientation (within the pipe wall), resulting in a pipe that is both lighter and mechanically superior.

Further, this alignment boosts the Material Rating Strength from around 25 MPa (PVC-U) to approximately 50 MPa in PVC-O, with peak tensile strength reaching near 70 MPa, as confirmed by performance data from Indian manufacturers.

The orientation process improves tensile strength, ductility, and impact resistance while reducing wall thickness. This leads to enhanced hydraulic capacity without compromising structural integrity. Biaxial orientation, in particular, reinforces the pipe in both hoop and axial directions, providing optimal performance under pressure and external loads.

Various global technologies support this process, including air-based systems developed by international pioneers like Molecor. Molecor develops and supplies orientation technology, including machinery and complete lines (like the TOM® system), to produce PVC-O pipes through molecular orientation. Their proprietary technology allows manufacturers worldwide to produce high-strength, high-efficiency PVC-O pipes in various classes and diameters.

Such technologies offer highly controlled orientation environments that ensure uniform material distribution and consistent quality along the length of the pipe. These systems have been adopted worldwide due to their reliability and efficiency.

PVC-O pipes are generally produced in pressure classes ranging from PN 12.5 to PN 25 and in nominal diameters (DN) from 90 mm up to 800 mm, depending on application and tooling capacity. The entire process is governed by standards such as ISO 16422 and IS 16647:2017 in India, ensuring global consistency in mechanical and hydraulic performance.

With the use of advanced orientation lines and in-line socketing technologies, manufacturers can deliver seamless, leak-proof pipes suitable for high-pressure water supply, irrigation, and urban infrastructure, offering a blend of engineering precision and sustainability.

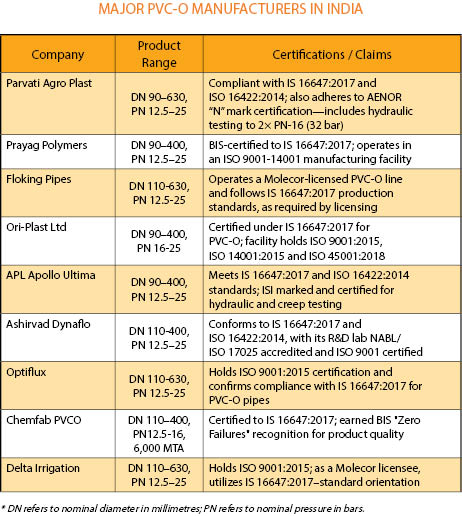

In India, manufacturers like Parvati Agro Plast and Prayag, along with others such as OriPlast, Floking Pipes, and APL Apollo, are now confidently delivering PVC-O using global standards across India. The result is a shift to plumbing-grade pipelines with higher hydraulics, longer life, lighter weight, and full compliance with PN 12.5–25, DN 90–400 mm, and IS/ISO standards.

Performance Edge | Efficiency, Durability, and Sustainability

“PVC-O Class 500 pipes offer between 15% – 40% more hydraulic capacity than pipes made from other materials (PVC-U, HDPE, ductile iron) with the same external dimensions,” states Molecor. Their mechanical strength is roughly double that of conventional PVC, with a significant increase in ductility and robustness against cracking.

Impact resistance under ambient conditions is twice as high and reaches up to five times greater at –18 °C, making them suitable for varied climatic conditions. These pipes use 35–40% less polymer material, yielding lighter pipes, lower logistical costs, and a smaller carbon footprint. “PARVATI PVC-O pipes offer between 15% – 40% more hydraulic capacity than pipes made from other materials with the same external diameters,” specifically notes Parvati Agro Plast. Chemfab Alkalis (Chemfab PVCO) also confirms the performance improvement, stating their PVC-O pipes provide 15–40% higher hydraulic capacity than traditional pipes using the same external diameter.

With a design life exceeding 50 years, some manufacturers attest to over 100 years, the product is both reliable and long-lasting. As per Parvati Agro Plast, “As long as it is laid down properly, installed and designed properly, it has been observed that OPVC life expectancy extends to more than 100 years.”

These performance attributes combine to translate into real-world benefits: field installations report smoother flow with fewer leak points and reduced maintenance. The oriented structure resists crack propagation and biofilm buildup better than PVC-U or metal counterparts such as ductile iron (DI) pipes.

As Chemfab notes, “PVC-O pipes offer a higher strength-to-weight ratio and improved flexibility. Thanks to molecular orientation, the wall thickness of PVC-O pipes is significantly lower than that of DI pipes. This allows for an increase of nearly 30% in hydraulic capacity, enabling a higher flow rate and better energy efficiency at similar diameters. These pipes also have greater resistance to internal and external stresses.”

For urban planners, it provides confidence in long-term service delivery; for farmers, it means more water at less cost; for engineers, it simplifies hydraulics calculations; and for policymakers, it aligns with carbon reduction goals by driving down pump energy and repeat replacements.

Indian Manufacturers in Action | Scaling the PVC-O Wave

As global awareness about sustainable, high-performance piping systems grows, Indian manufacturers are rising to the occasion, scaling up production and adoption of PVC-O pipes across infrastructure, agriculture, and water supply networks. The presence of orientation-capable production lines, based on patented technologies licensed from global leaders like Molecor, has catalyzed this movement.

One of the frontrunners in this transformation is Parvati Agro Plast, a Sangli-based company that manufactures PVC-O Class 500 pipes under IS 16647:2017 and ISO 16422 standards. The pipes range in diameters (DN) from 90 mm to 630 mm (while extended specifications up to 800 mm are also detailed in the company’s technical literature) and are available in pressure (PN) classes from 12.5 to 25 bars. With orientation technology embedded into their process, the company boasts products that offer 40% material savings, a 100+ year design life, and tensile strength exceeding traditional PVC-U and even some metal counterparts. Their lightweight yet robust pipes are well-suited for agriculture and high-pressure water transport systems. In October 2023, the company’s business was acquired by The Supreme Industries Ltd., which has since integrated the Sangli facility as part of its broader expansion in high-performance piping systems.

Similarly, Prayag Polymers, operating out of Bhiwadi, Rajasthan, is another major player. With a long-standing reputation in the sanitary and plumbing segments, Prayag has diversified into advanced piping systems and now produces PVC-O pipes in pressure (PN) classes ranging from 12.5 to 25 bars and diameters (DN) from 90 mm to 400 mm. The company has invested in in-house testing labs and claims hydraulic efficiency improvements of up to 40% compared to conventional systems. Its orientation process reportedly ensures high resistance to fatigue and water hammer.

Chemfab Alkalis Limited (Chemfab PVCO), located in Sri City, Andhra Pradesh, operates a zero-discharge PVC-O plant commissioned in 2021. With two production lines totaling approximately 6,000 TPA, Chemfab’s facility manufactures pipes in PN 12.5 and PN 25 classes across DN 110 to DN 400 mm, along with a full range of fittings. The company emphasizes eco-friendly production and compliance with IS 16647, earning BIS “Zero Failures” certification for quality assurance. “We are proud to announce that Chemfab has been awarded the prestigious Zero Failures Certificate of Appreciation from the Bureau of Indian Standards (BIS) – a first in the PVC-O Pipes Industry,” announced the company.

Delta Irrigation LLP, based in Kolhapur, Maharashtra, is also a verified PVC-O pipe producer. Their “Delta Aqua” range includes PVC-O Class-500 pipes from DN 110 to DN 630, pressure-rated from PN 12.5 to PN 25. The company emphasizes green production with zero-heavy-metal stabilizers and energy-efficient, push-fit spigot joints. The facility holds ISO 9001:2015 certification, and Delta promotes its PVC-O pipes certified as per IS 16647:2017 for high-pressure water and irrigation applications.

Another key name is Ori-Plast Ltd., headquartered in Kolkata. Ori-Plast’s growing PVC-O range adheres to IS and ISO norms and caters to the needs of agriculture and drinking water applications. It makes PVC-O pipes complying to the Standards IS 16647 : 2017 from DN 90 mm to 400 mm and from PN 16 to 25 bars. The company highlights energy savings, higher flow rates, and crack-resistance as central to its PVC-O offering. Their orientation lines, enabled through advanced extrusion and biaxial stretching modules, ensure dimensional stability even under high-pressure cycles.

APL Apollo, a prominent steel tubes manufacturer, has also entered the plastic piping segment and offers a portfolio that includes PVC-O. The company launched Ultima PVC-O Pipes as per IS 16647: 2017 and ISO 16422 in diameter (DN) ranging from 90mm to 400 mm and pressure (PN) from 10 to 25 bars. The firm markets its solutions as lighter and longer-lasting, targeting green building and high-end irrigation applications. The company’s brand strength, expansive distribution network, and technical support make it a strong contender in the evolving PVC-O ecosystem.

Floking Pipes Pvt. Ltd., with a focus on agricultural irrigation and pressure piping systems, is among the first in India to adopt licensed orientation lines. Their PVC-O products, PVC-O Class-500 pipes from DN 110 to DN 630, pressure-rated from PN 12.5 to PN 25, reportedly meet national specifications (IS 16647: 2017) and deliver strength, flexibility, and longevity in equal measure.

Ashirvad Pipes, part of the Aliaxis Group, markets its PVC-O range under the brand name Dynaflo. Built to IS 16647:2017 / ISO 16422 standards, these PVC-O pipes, handling PN 12.5 to PN 25, offer enhanced impact strength, flexibility, and long-term durability, backed by global R&D and certification.

Optiflux Pipe Industries, headquartered in Jodhpur, manufactures biaxially oriented PVC-O pipes and emphasizes its R&D-driven, ISO-certified production systems. Their OPTIFLUX Class 500 Pipes are available in the ranges DN 110-630 mm and PN 12.5-25 bars. The company has a large manufacturing footprint and serves both municipal and industrial water applications.

Leading PVC companies such as Prince Pipes, Astral, Supreme (which acquired Parvati), and Finolex possess resin-making capabilities and scalability, positioning them to expand in PVC-O.

Together, this diverse supplier base spans from SMEs to large industrial players, indicating both broad interest and capability in PVC-O. It also suggests growing competition that may accelerate affordability, innovation, and access, turning PVC-O from a specialist to a solution that can be adopted at scale.

Also Read: Goodluck India Accelerates Growth with Defence and Aerospace Foray

Market Outlook & Policy Fit | Why PVC-O Matters Now

Forecasts from Research & Markets suggest India’s PVC-O market, valued at approximately USD 90 million in 2024, will expand to USD 2.5 billion by 2034, a CAGR of about 28%. Demand is propelled by irrigation, village water networks, and industrial pipelines, supported by the D70,000 crore Jal Jeevan Mission and Smart Cities Mission. Maharashtra remains the adoption leader, with Central and Eastern states following suit.

Standards from BIS and ISO have incorporated PVC-O specifications, aligning materials with goals for leak-resistant, energy-efficient infrastructure. Challenges include limited global capacity for orientation-capable machines and hesitancy from some state agencies to adopt higher-grade materials due to cost structures and entrenched procurement behaviors. Nonetheless, mounting evidence, growing awareness, and tighter standards are fueling momentum.

In states leading the Jal Jeevan rollout, engineering teams report 30–40% reductions in pipe replacement cycles and reduced leakages where PVC-O has been piloted, though detailed government audits are pending. The material is gaining attention from ministries and agencies as climate-resilient infrastructure that also supports net-zero goals via energy and emissions savings across supply chains and lifetime use.

Time for Adoption at Scale

PVC-O is not merely a material upgrade; it marks a paradigm shift in India’s water infrastructure. By delivering superior strength, fluid capacity, resilience, and sustainability, it satisfies both national mission objectives and the real-world demands of pipelines designed to last half a century or more. To mainstream PVC-O, stakeholders must enforce procurement standards, equip installers with training, and manufacturers should present robust performance warranties and third-party test data. As adoption scales and awareness deepens among planners, engineers, and contractors, PVC-O is set to become the gold standard for high-performance, resilient, and sustainable piping systems across India.

Disclaimer: The facts, figures, and product specifications presented in this article are based on publicly available sources and company literature as of the time of writing. They may not reflect the most current data, certifications, or commercial status. Readers are advised to verify information with manufacturers for the latest updates.