Crippa was established in 1948 by Agostino Crippa as a sole proprietorship and became a limited company in 1977. Today Crippa is a strong, cohesive industrial group that combines the expertise of Crippa S.p.A. and SMI S.r.l. to provide tube process technology. For over a half-century, we have been designing and producing machines for bending and working metal tubes. The company has been internationally recognised as a leader in this field, distinguishing itself for the high quality, productivity, and level of innovation of its machines and solutions.

In an interaction with Tube & Pipe India, Mr. Carlo Fratini, Business Development Manager, Crippa S.p.A., talks about the company’s business journey, product range, and future plans.

“We have been the first producer in the world to have a fully electric machine, multi-radios with the capability to cut the tube in the cycle to make the most complex geometry… Most of the machines we produce are fully electric to minimize their environmental impact”

Tube & Pipe India: Please tell us about your company highlighting its presence in India.

Carlo Fratini: Crippa is a worldwide point of reference in tube processing: we are present with our personnel on all five continents including India. We have been working in India for many years with our agent and serve the top brands for automotive and aircraft, as well as furniture, heat exchangers, and air conditioning.

TPI: Tell us a bit about your manufacturing capabilities and product range.

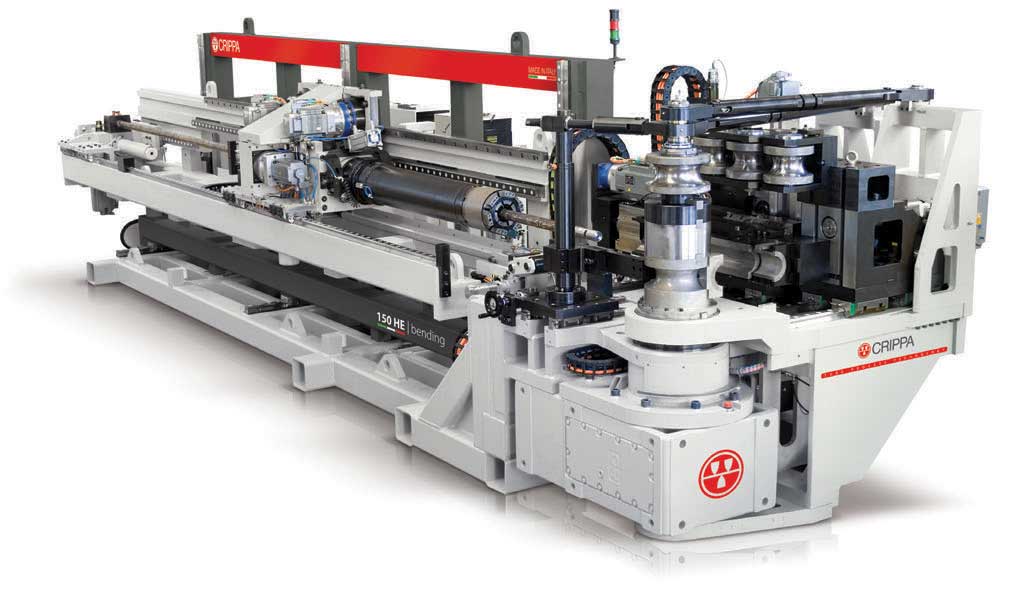

CF: The Crippa group provides complementary industrial solutions for tubes from diameters 0.5’’ to 11’’. We offer a comprehensive product range, designed to respond to every type of work. We provide specific, transversal, and highly customised tube solutions in synergy with our customers. The lead time is in accordance with our customer requests ranging from two months to six months, depending on the solution. In addition to tube bending and end-forming machines, we design customised work cells or special machines for sector-specific processes. We always guarantee the best cycle times with the highest reliability and repeatability.

TPI: Has there been any new development at Crippa?

CF: Absolutely! We have a lot of competitors and every year, we put something on the market to remain the pioneer. We have been the first producer in the world to have a fully electric machine, multi-radios with the capability to cut the tube in the cycle to make the most complex geometry in the world. Everything we produce is fully electric. Crippa has always integrated sustainability into its business strategy. Most of the machines we produce are fully electric to minimise their environmental impact through CO 2 emissions and enable our customers to use renewable sources of electricity to power their machines.

TPI: What are your future plans?

CF: We have an eye for new technology, and in the future, there will be more fully electric vehicles. Hence, we are developing new technology, keeping in mind that sooner or later, the conventional engine would be banned.

TPI: What are the strengths of your company and how do you look forward to the Indian market?

CF: Our strength is that we always produce something new. Our machines are designed and made to last for years. Our customers have known Crippa for a long time. And if we are able to provide our machine in their facility, they will never change again.

Also Read: Salzgitter Places Large Order with Primetals Technologies for Electric Arc Furnace

We see big potential in India. We have a very good and long relationship with our local agent in the Indian market – Pradman Engineering Services Pvt. Ltd. There are many key players in the aerospace and automotive industries of India who could be our potential customers. We are investing a lot and will start marketing our products in India this year by making our product available in the exhibitions. We’ll participate at the METEC India event to be held in Mumbai from 23 to 25 November, 2022, and our stall would be M141. This summer, we also attended the Himtex Expo, where we showed a linear machine.

“Most of the machines we produce are fully electric to minimise their environmental impact”