The infrastructural growth is an integral part of any country’s development, hence, a sensible investment on India’s part. BST Infratech Limited is among the companies who are supplying developmental materials to the key projects of government-owned corporations, like PGCIL, Central Railway Electrification Organization (CORE) Prayagraj, etc. Mr. Rohit Pareek, Chief Marketing Officer & Spokesperson at BST Infratech Limited, shared with Tube & Pipe India that, to meet the growing demand the company is aiming to grow its MS ERW & GI pipes production capacity to 2,50,000 MTPA by 2024, and their gross revenue to over INR 2,000 crore, in the upcoming five years. This is in addition to the expansion of their existing factory premises, equipment setup, distribution network, and R&D scope.

“The global ERW pipes and tubes market, worth millions, is expected to experience an expanding national and global demand fueled by automobiles, construction, and oil & gas sectors.”

Tube & Pipe India: Please share BST Infratech’s journey, including history, major milestones & achievements.

Mr. Rohit Pareek: BST Infratech Limited began its impressive journey twenty years ago in 2007, under the leadership of an eminent entrepreneur, Mr. Gopal Kumar Agarwal, Managing Director of BST Infratech Limited. Mr. Agarwal’s dedication and expertise helped the organization to grow from a local iron manufacturing company to one of the most respected iron and steel products manufacturing companies in the industry. The secret to our organization’s success lies in the humble wish to produce high-quality iron and steel products for all sorts of construction work and apply all our available resources to this.

Mr. Rahul Agarwal, Mr. Agarwal’s son, has followed in his father’s footsteps to further the market position of the company as well as strengthen our brand image in the minds of all our customers. He has incorporated various new policies and ideas into the manufacturing and supplying processes that have proven beneficial in the growth and profitability of the company. He has made it a practice for our company to regularly invest time and resources into market research and development, enabling us to deliver quality goods.

We are now targeting a profit margin of over INR 2,000 crore within a span of five years.

TPI: Tell us about your manufacturing setup, production capacities, capabilities, and equipment employed.

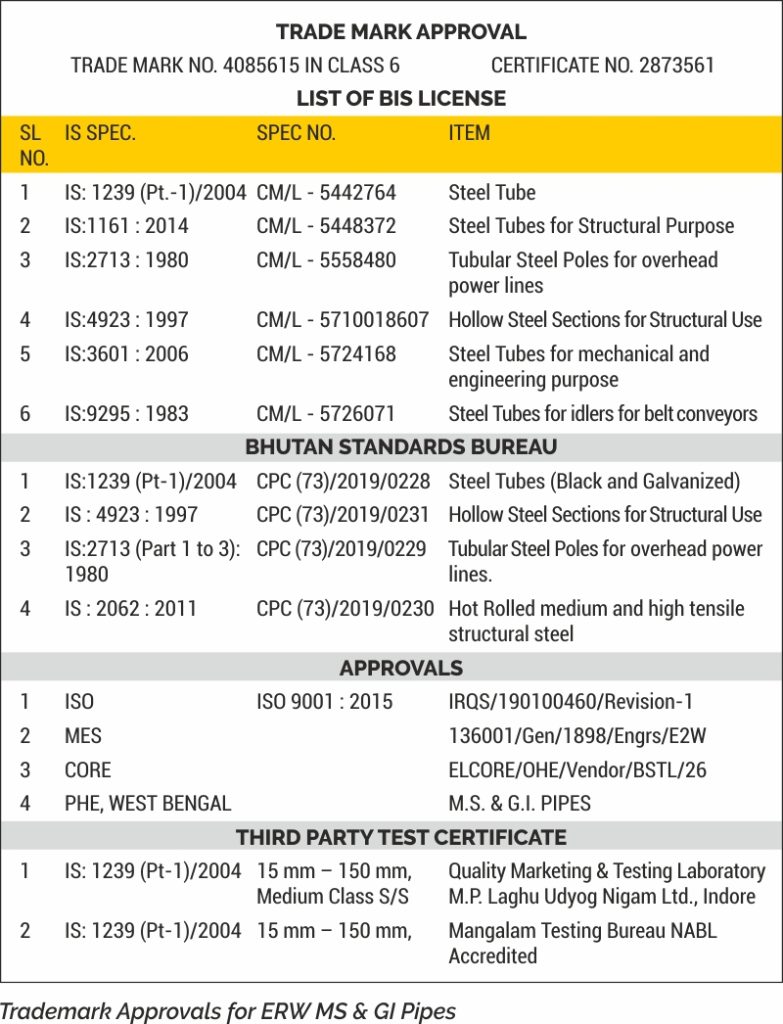

RP: BST Infratech Limited is an ISO 9001 and 14001 certified company. We are committed to manufacturing quality products in terms of dimensional accuracy, or design, and galvanizing coatings, in accordance with Indian and international standards. Our manufacturing site houses a progressive structural mill and is based in Mondalpur, Jamuria Industrial Estate, Burdwan West Bengal, spreading over 19 acres. The plant houses a progressive structural mill. The manufacturing setup includes multiple sheds for fabrication work, installed with EOT cranes and different CNC and conventional machines, and the latest technology-equipped galvanizing plant.

We also have an in-house testing facility with 32 elements of Spectra analysis and 100 tonne UTM machine, an in-house testing facility for galvanizing tests, and training rooms for the skill development of employees.

At our plant site, we manufacture a variety of hot rolled products, MS & GI pipes, metal beam crash barriers (W & Thrie Beam), swaged-type tubular poles, etc. Presently, we produce around 36,000 MTPA of iron and steel products, and our products are Bureau of Indian Standards (BIS) approved and marked licenses certified, designating the authenticity of our entire product portfolio. BST is approved for transmission up to the rating of 765kVA in Power Grid Corporation of India Limited (PGCIL) for supplying the G.I. structures.

TPI: Please tell us about your product portfolio.

RP: BST Infratech Limited’s primary mission is to maintain high standards of precision, quality, and punctuality while displaying technical soundness and construction effectiveness in all our deliverables. This practice is visible in all the manufacturing processes and procedures of even the simplest of our products. Our basic range of products comprises MS HR strips, MS ERW pipes & GI pipes, metal beam crash barriers, MS wire rod & HB wire, swaged-type steel poles, power transmission towers, OHE galvanized structures & cantilever bracket tubes/guide tubes for railways, and TMT bars.

BST Infratech Limited has engaged all its efforts and resources into providing top-class MS ERW pipes and services to all our valuable dealers, distributors, and fabricators. We have frequently focused on the affordability and sustainability of our MS ERW pipes. We manufacture over 100 sub-categories for our MS ERW & GI pipes segment, varying in shapes (round and square, and rectangle MS ERW pipes) and sizes (ranging from 15-200 NB). We have plans to expand our production capacity from nearly 1,50,000 MTPA to 2,50,000 MTPA in the next year.

We manufacture about 40,000 MTPA of metal beam crash barriers (W & Thrie Beam), which we get crash tested by prestigious organizations like NATRAX. We have an installed production capacity of approximately 36,000 MTPA for GI steel structures. We supply GI steel structures to SEBs and EPC contractors who take up projects for State Electricity Boards or Power Grid Corporation of India Limited for erecting transmission line towers, sub-station structures, and other rural electrification projects across India. Currently, in the swaged-type tubular poles segment we are fabricating pole lengths ranging from 7-16 meters at a rate of about 12,000 TPA while following the IS: 2713 standards.

I ensure the presence of a highly-competent sales team in market so that our services remain uninterrupted.

“We plan to increase our pipe production to 2,50,000 MTPA in the next financial year.”

TPI: Please elaborate on BST Infratech’s market footprint and major clientele.

RP: We have a pan-Indian presence and rely on our distributor network for hassle-free customer satisfaction. Our major dealers and distributors help us to maintain our supply and sales chain for several products across every corner of the country. Apart from India, we have also exported to various ambitious projects and assignments in Bhutan, Nepal, and Europe.

We serve BHEL, Larsen & Toubro, South Eastern Railways, BSF, and MES, among others in the MS ERW pipes segment, HR Grade (SAIL) raw material.

We supply GI pipes to Public Health Engineering Department (West Bengal), Uttar Pradesh Jal Nigam (Government of Uttar Pradesh), the Public Health Engineering Department (Manipur), the Drinking Water & Sanitation Department (Government of Jharkhand), Ministry of Defence, Andaman-Lakshadweep Harbour Works (Port Blair).

We have supplied metal beam crash barriers (W & Thrie Beam) to Larsen & Toubro Limited for Upper Indravati Irrigation Project in the district of Kalahandi Odisha; Tata Projects Limited for Gurajanapalli – Polekuru (NH -216 Road Project), Losari-Machavaram section (NH 214 A – New NH 216); PNC Infratech Limited for Purvanchal Expressway (Pkg – VI); Oriental Structural Engineers Private Limited for Purvanchal Expressway (Pkg – VIII); Iron Triangle Limited for HPCL Rajasthan Refinery Project (Barmer, Rajasthan); Gawar Construction Limited for Bundelkhand Expressway (Pkg – IV, V & VI); and Ashoka Buildcon Limited for Bundelkhand Expressway (Pkg – III).

We have supplied swaged-type tubular poles to Laser Power & Infra Private Limited, Bhutan Power Corporation, and NK Power, and are currently supplying for different projects commissioned by PGCIL, West Bengal State Electricity Distribution Company Limited (WBSEDCL), Assam Power Distribution Company Limited (APDCL), Tripura State Electricity Corporation Limited (TSECL), Nagaland Power Department, etc. through turnkey contractors.

We are supplying products for EHV transmission & substation erection to PGCIL, Rajasthan Rajya Vidyut Prasaran Nigam Limited, Madhya Pradesh Power Transmission Corporation Limited, Uttar Pradesh Power Transmission Corporation Limited, South Bihar Power Distribution Company Limited, North Bihar Power Distribution Company Limited, Jharkhand Urja Sancharan Nigam Limited, and Odisha Power Transmission Corporation Limited.

Our clients in Railway Overhead Electrification products include Central Railway Electrification Organization (CORE) Prayagraj, Rail India Technical and Economic Service (RITES), Tata Projects Limited, KEC International Limited, Kalpataru Transmission Power Limited, Bajaj Electricals, Ashoka Buildcon Limited, Larsen & Toubro, Siemens, Shyam Indus & Zetwerk.

TPI: What is your company’s USP?

RP: We house the most advanced machinery and equipment at our plant. The up-to-date equipment helps us integrate new innovation and technologies in the production of our product portfolio, which comes out as among the best present and market and guarantee our customer’s satisfaction. Additionally, our esteemed directors have market experience and knowledge spanning more than 25 years and they are well-versed in how to market a good product for the best possible results.

There are four pillars for any organization, material, machine, man, and money. We invest as much in our manpower as we do in other segments, and we have a fleet of highly qualified employees whose knowledge and wisdom, especially among the senior management ranks, help us build on our product quality USP.

Lastly, a strong distribution network is non-expendable in the present times. Our strong and cooperative network helps us service our customers smoothly and instill in them the belief “They are BST’s priority”, which in turn contributes to our growth.

“We always believe in creating a delighted customer and not just making a sale.”

TPI: What is your company’s technological and business roadmap?

RP: Our entire roadmap is based on twin driving forces of quality & affordability. We are always trying to build farther on our basic roadmap by producing even better products and have a strong ambition to expand our manufacturing capacities. We plan to increase our pipe production to 2,50,000 MTPA by 2024. In terms of gross turnover as well, we aim to grow from INR 1,325 crore to over INR 2,000 crore within next five years.

I can safely say that our reliance on maintaining quality in our products, while integrating market competitiveness, has helped BST Infratech Limited to become a preferred choice of our customers, within a comparatively short span of 20 years. We are aware of how important the iron and steel industry’s contribution is to Indian growth and development, and it is our desire to be a part of this growth in a significant manner.

Also Read: Grow Ever Steel Follows a Five-Point Strategy to Grow with Market Trends

TPI: Can you elaborate on the global & Indian market trends of tubes & pipes industry? Which trends do you identify emerging as drivers of industrial growth?

RP: The global ERW pipes and tubes market, worth millions, is expected to experience an expanding national and global demand fueled by automobiles, construction, and oil & gas sectors. The iron and steel industry has been compelled to increase its production capacity and allocate more funds toward manufacturing relevant products. This trend is a major driving force behind future industrial growth.

The developing economies are prioritizing investment in infrastructural projects to facilitate urbanization, hence driving our industry to direct their efforts and resources towards supporting the trend. Booming urbanization often drives increased demand for infrastructure, including the tubes and pipes industry. The growing urban population requires better water supply, sewage systems, and transportation, leading to a rise in construction projects and the need for various types of tubes and pipes. This trend can significantly impact the industry’s growth and opportunities for businesses and investors.

These trends consequently drive the current production design of BST Infratech while inspiring future plans.

TPI: Please explain in detail about your recent developments and plans for the future.

RP: We have plans in varying segments to aid the growth of our coming by the end of the current FY and even going forward. We have brought in new machinery and equipment, an accomplished R&D team, and efficient executives at our Jamuria-based factory. We will increase the production capacity of high-quality MS ERW and GI pipes from 1,50,000 MTPA to 2,50,000 MTPA by 2024, to meet the growing demand. We are targeting a turnover of INR 2,000 crore for this FY.

While we are prioritizing diversi-fication of our product range in the upcoming months, we have plans to expand our factory area so the new equipment can be added to our current capacities. We have plans to increase our annual production of pipes and also our gross turnover. Finally, we have introduced new schemes to add new dealers and distributors to our network as we plan to venture into new market territories in future.