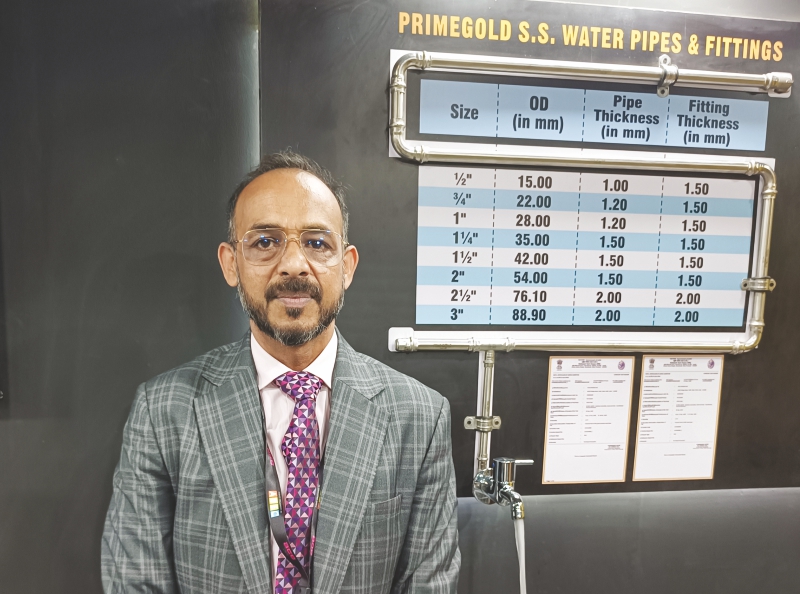

Prime Gold S.S. Pipes has been working since 2004 to provide hygienic and long-lasting steel pipes alternative to galvanized iron, copper, and plastic pipes in India. While their strengths have earned them reputed and lasting deals with the Indian government, renewable energy sector, food and beverages industry, and hospitals and pharmaceutical sector, the journey is still long and challenging, especially with the presence of numerous plastic pipe manufacturers and European and Chinese imports. Mr. Nimit Varshney, Vice President of Prime Gold Group, connected with Tube & Pipe India, to share all about the company’s challenges, achievements, product supremacy, and future plans.

Tube & Pipe India: Could you please give us a brief outline of your business journey and crucial milestones?

Nimit Varshney: Prime Gold Group initiated its S.S. Pipes vertical in 2004 with a vision and foresight of bringing the world a strong and secure living. We started manufacturing stainless steel plumbing pipes about 20 years ago and are one of the pioneers in the Indian pipe industry. Earlier zinc galvanized iron pipes used to be threaded for plumbing applications, which due to the rusting process would deteriorate causing leakage and seepage to destroy the plumbing network of the building or infrastructure. We are among the first manufacturers of stainless steel pipes in India.

TPI: Kindly cast some light on the infrastructure, manufacturing capabilities, and machinery installed at your facility.

NV: Prime Gold S.S. pipes are manufactured at our factory in Alipur, Delhi (India). We buy steel strips from Jindal Stainless Limited and manufacture steel pipes through Pressure Resistance Welding (PRW) process. Once pipes are ready we use the selected batches to manufacture pipe fittings of different sizes, based on pipe size. We manufacture ½′ to 6′ outer diameter pipes and more then 200 types of fitting.

TPI: Tell us about your product portfolio along with its key strengths and applications.

NV: We use 316L surgical-grade stainless steel to manufacture our pipes, and SS 304 food grade stainless steel pipes and fittings, like Tee, Socket, Reducers, Elbow, Union, etc., which are not only strong and non-perishable but also hygienic. Our biggest market competition is with plastic pipes, however, they are not considered hygienic for many industries, such as food and beverages and pharmaceuticals. Hence, our products have a high level of application in these industries. Our product line is Central Public Works Department (CPWD) approved.

TPI: What are the recent developments and future plans at your company?

NV: We are among the few stainless steel pipe manufacturers in India, so we have direct competition from Chinese and European exporters. However, there are many industries where it is mandatory to use stainless steel applications, and we are gaining recognition slowly. Presently our focus is to retain our existing clientele and build upon the numbers. Though we have been fortunate to find approval and support from the Indian government, who makes it mandatory for certain sectors and infrastructures to use stainless steel pipes for plumbing, we have aspirations to increase our production capacity, reach, and applicability and venture deeper into commercial projects.

TPI: Please shed light on your market footprint and clientele.

NV: Although the Indian pipes industry is dominated by plastic pipe manufacturers and foreign imports, we have managed to build a respectable and loyal clientele. We have worked along with National Buildings Construction Corporation (NBCC) Limited and among our prestigious private sector contracts is the Ambience builder range of New Delhi and Gurugram. You can find our applications in food & beverage industry like Haldiram Snacks, various hospital & pharmaceutical industry projects, 5-star hotel projects, commercial projects and various industrial projects like metal industries & construction projects. We also have a joint venture with SAIL for iron rods, which we have been manufacturing for 35 years. Some of the government projects we have heralded include pipes and plumbing at Jaipur Railway Station, Gandhi Nagar Railway Station in Jaipur, CPWD, Ministry of Water Resources in New Delhi, and Uttar Pradesh Nirman Nigam in Lucknow.

Also Read: Jyoti Inox Private Limited: Providing Stainless Steel Solutions

TPI: What is your outlook on the tube and pipe industry? What do you believe is its future?

NV: The stainless steel pipes market in India is still in the developing stage and is a very niche market due to competition with the plastic plumbing market, which is less costly, and has numerous manufacturers. However, we have faith in our product, it is not only hygienic and deterioration-proof, but it is also easily recyclable, installable, and rust-proof. Since the material mass density of steel is less than iron, it is a long-lasting alternative to galvanized iron pipes.

TPI: Do you have any dealers and distributors in India?

NV: We have many reputed customers in India. We continuously sell our products to contractors involved in fluid transportation in sectors like thermal, solar, and nuclear power, the oil and gas sector, refinery and petrochemical, dairy, chemical, fertilizer, defense, aerospace, and construction. We have a well-qualified and experienced marketing team for serving our product in various states of our country. Our group has a well-developed network of Dealers/ Distributor/Stockist exclusive sale depots spread over various states of India which includes the states of Delhi, Haryana, Rajasthan, Punjab, UP, Karnataka, & Maharashtra.