Copier Machinery considers its customized solutions and rapid support and service as its greatest strengths. The Netherlands company offers a wide range of pipe preparation machinery portfolios and emphasizes on innovation, stability, reliability, and high quality. Mr. Jan Copier, CEO and Owner, was interviewed by Tube & Pipe India at the recently held Steelfab Sharjah Expo. He shared with us his company’s profile, work, and future plans of bringing to market developments worked out in the last 10 years.

Tube & Pipe India: Could you please give us a brief outline of your business journey and crucial milestones?

Jan Copier: Copier Machinery started as a steel construction and machine building company in 1997 in the Netherlands. In 2000 we acquired Cornelissen and in 2010, after establishing Copier Bevelmachines, we started to sell under the Copier brand. In 2016, we acquired Arla, a German company, and expanded to the USA in 2018, and we started to use Copier Machinery as a brand name, because we developed much more than only machines for bevelling. As of now, our engineering and manufacturing plant is based in our headquarters in Giessen, The Netherlands, together with our sales department. We also have a sales office and warehouse based in Broken Arrow, Oklahoma, to support our USA customers. We work on a new subsidiary in Dubai to support the Middle East and surroundings. We strongly believe in having a local presence to optimize customer support. We specialize in rotating tool lathes (RTL) and make solutions and tools for the tubes and pipes industry. 60% of our orders are standard solutions or machines, 35% are modified standard and 5% is a one-off solution.

TPI: Kindly cast some light on the infrastructure, manufacturing capabilities, and machinery installed at your facility.

JC: The plant at Giessen, The Netherlands, is our manufacturing unit and all our production work is concentrated here. We have a 1500 square meter facility with offices, shop and warehouse. We design, engineer, program, and assemble all our machines in-house, but outsource the production of our parts. Our focus remains on designing, assembling, installing, application training, and maintenance of the machinery. We also provide accessories and devices to assist the application of our machines.

TPI: Tell us about your product portfolio along with its key strengths and applications.

JC: We manufacture special lathes for machining long products like pipes and bars. We also offer solutions towards automation, which contain pipe handling, connections with ERP systems and remote control. We are in several markets, like pipe spool production, pipe production (pipe mills), pipe piling, hydraulic cylinder production and shipbuilding.

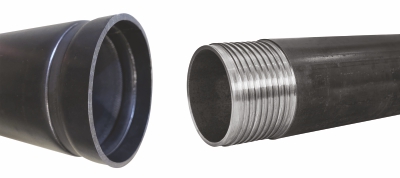

For these industries we have solutions in a wide diameter range, from 1/2 “up to 65”. As already mentioned, we specialize in RTL which works differently than traditional lathes, as the workpiece remains static and the tool rotates, machining the pipe or bar. We have solutions that work with form-tools or with single point machining (CNC controlled). We can offer solutions with short cycle-times, or solutions easy to automate and can run with less operational costs.

Another market we are in is fire protection. We provide solutions and machinery that can roll-groove or cut-groove pipes for sprinkler installations.

We also provide various accessories and devices to assist our working, such as tooling, inside/outside diameter tracking, pipe roller bench, clamping devices, drive and groove rolls, grooving roller bench, and lift and turn.

TPI: What are the recent developments and future plans at your company?

JC: Although we have already sold over 400 machines and systems in over 40 countries, we are focused on expanding our sales and service by increasing and extending our local presence. We have also done a lot of research and development work in the last 10 years and plan to launch upgrades into the market. Additionally, we sense the market is still moving in favour of more automation and we offer customized solutions in this area. You can select any of our advertised products and get them customized to your requirements, or you can come to us with your requirements and we could engineer a solution most suitable for you.

TPI: Please shed light on your market footprint and clientele.

JC: We have clients in over 40 countries across the world, and about 95% of our revenue comes from exports. Although our strongest markets are Europe and the USA, the performance varies with the Far East and Middle East market performing better in some years. Our clientele includes all the industries where tubes and pipes have applications, such as pipe spool fabrication, pipe mill, pipe piling, marine and offshore, fire sprinklers, hydraulic cylinder production, automotive, and industrial boilers.

Also Read: Bhavya Machine Tools: One-Stop Shop for all Machinery Needs

TPI: What is your outlook on the tube and pipe industry? What do you believe is its future?

JC: There is an overall shift in the global economy as world preference is shifting from the oil and gas sector to renewable and clean energy sources. Although the tubes and pipes industry shall be following the trend, the oil and gas sector still has 10-15 years available to continue dominating the world economy. Additionally, we see the development of complex materials and metals and an increase in automation. Also there is a big development in data logging and analysing. There is considerable growth expected in this field as the production data gets analysed and production systems can get optimized.

TPI: What is your technology and business roadmap for the future?

JC: Although we started manufacturing CNC piping applications eight years ago, in 2014, there is still development and sales increase possible. So, our focus shall be on increasing CNC’s market appearance and developing data logging technology. More conventional production machinery will develop further, because machine building is also developing, one example is 3D printing which gives more freedom to have optimized design solutions against lower costs. Data logging will help customers to improve their production efficiency and reduce their maintenance costs, and we can support them.

TPI: What are your opinions about the Indian market?

JC: Geopolitics has a strong impact on our business and we try to remain in step with it to ensure profitability. Also we believe that good cooperation between suppliers could improve profitability for customers. Moreover, as the projects become bigger the scale of investments grows and processes get diverse and automated. Cooperation and collaboration can help us to provide better solutions to our customers. We already have contacts in India and have the ambition to bring solutions to the Indian market, and support customers to be successful in their markets.